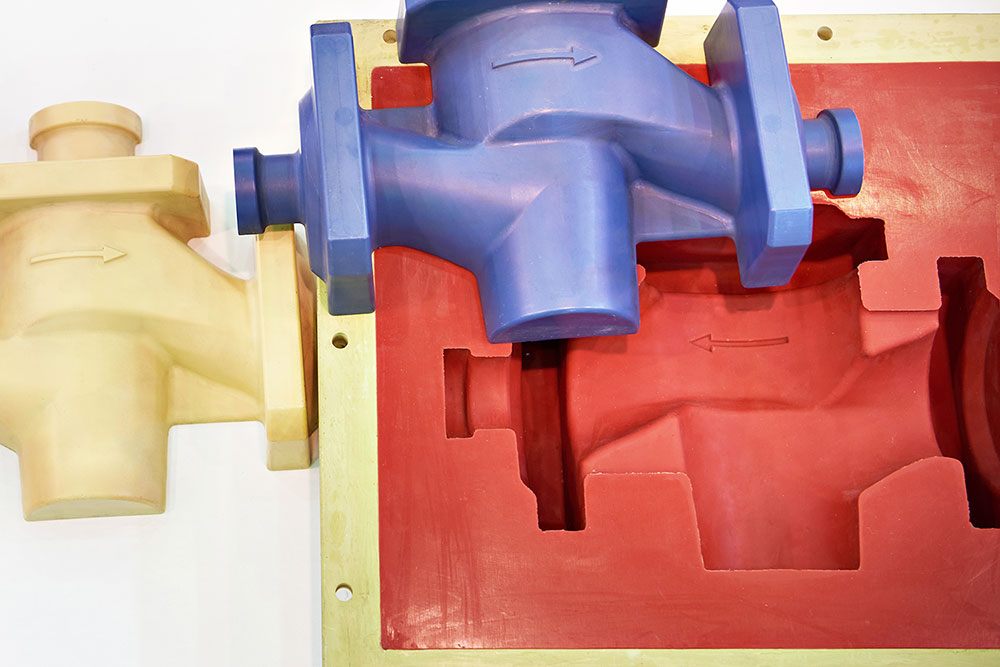

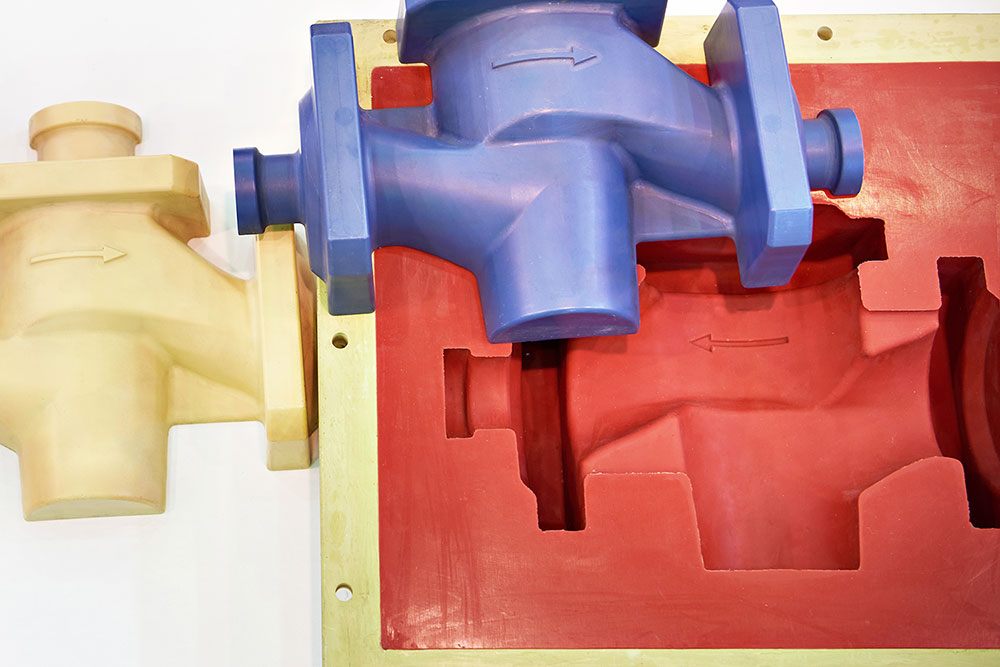

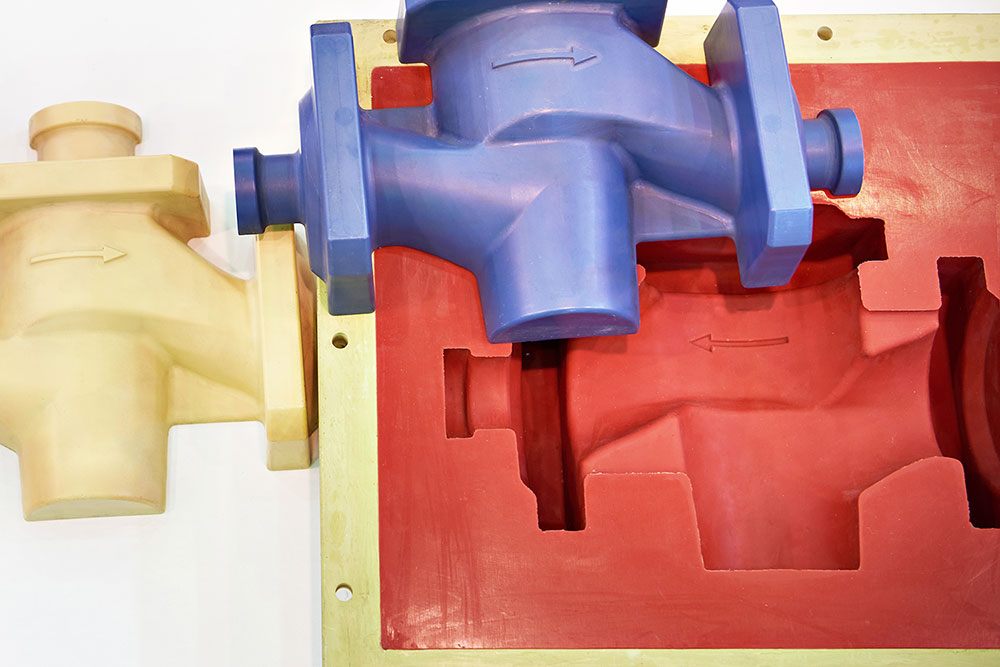

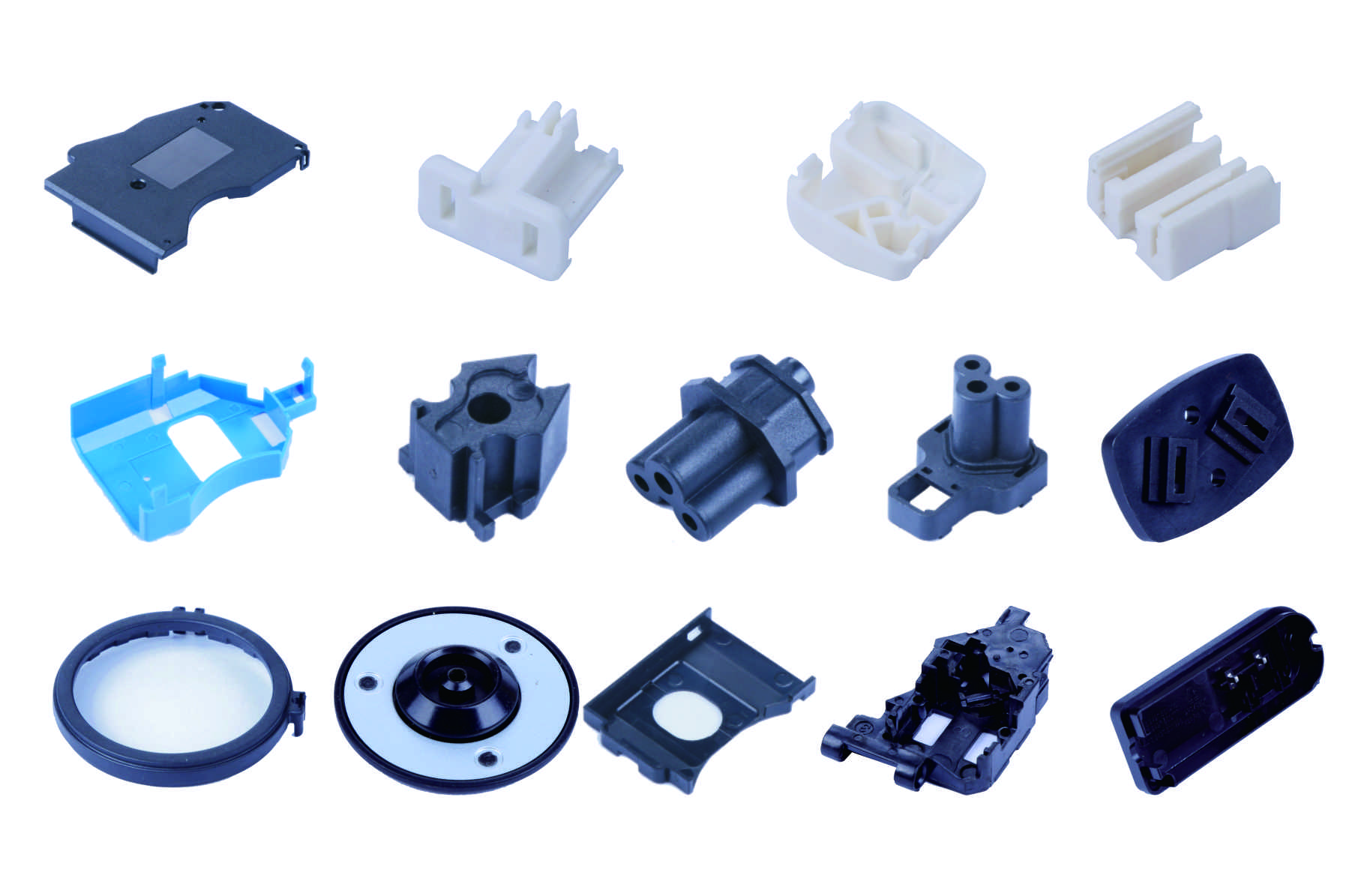

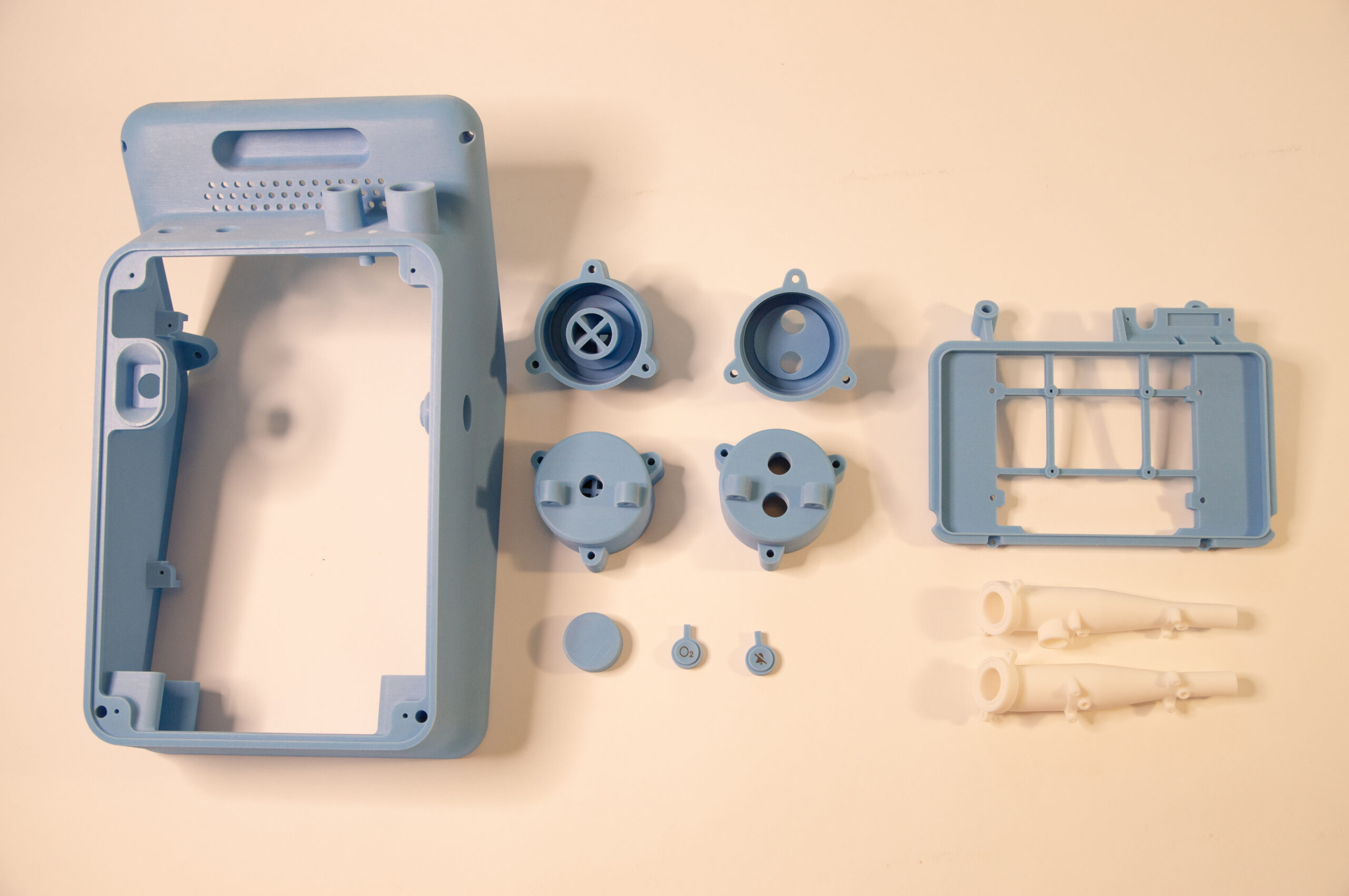

CreateProto uses vacuum casting technology to create silicone rubber molds, casting urethane parts quickly and accurately for functional tests, pre-production parts, and design verification for inexpensive low-volume production, cutting the need for investing in metal tooling.

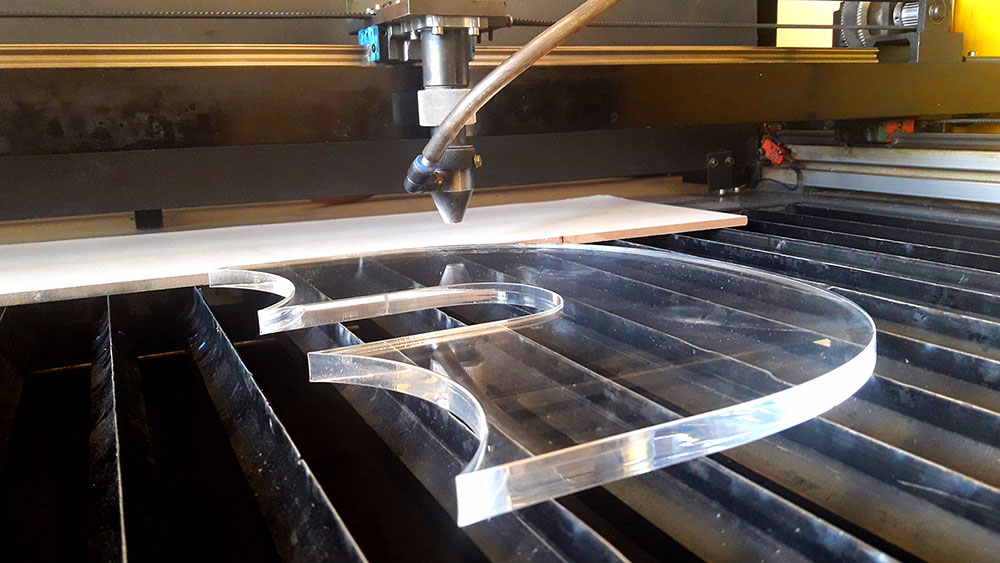

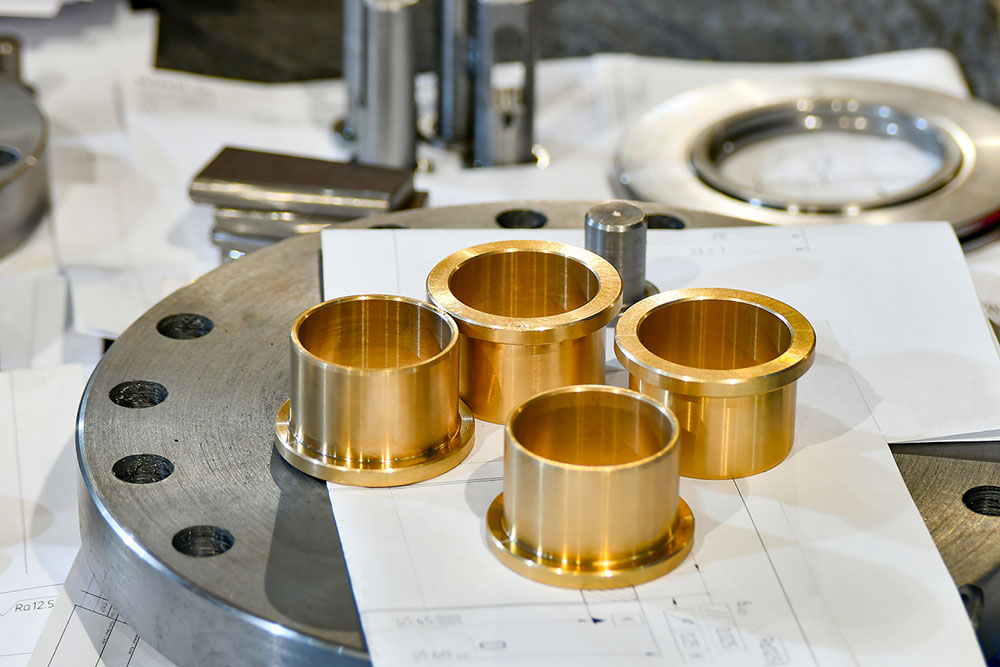

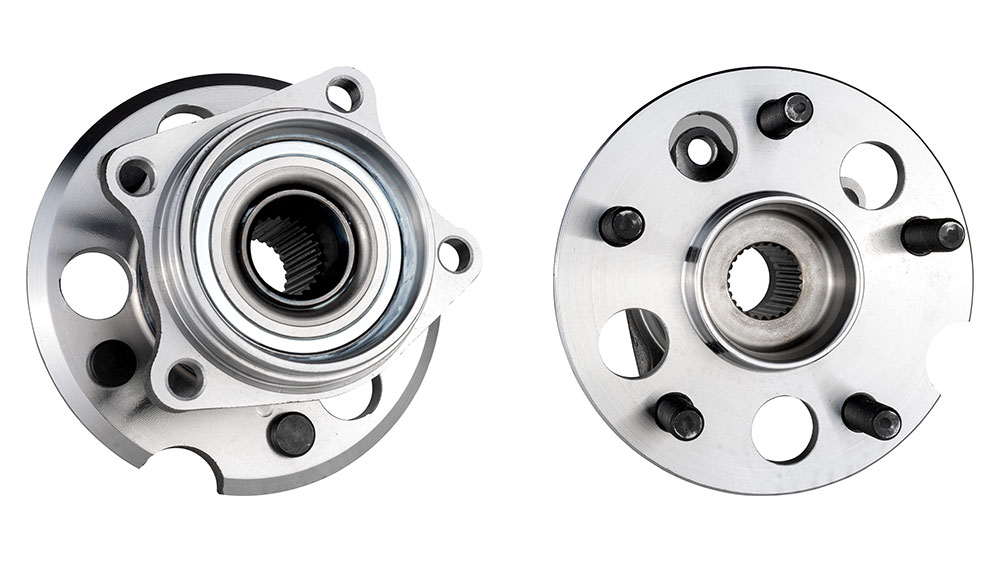

Precision meets excellence with our CNC machining services at CreateProto. Elevate your projects with high-quality, custom parts. Explore the art of manufacturing at its finest.

Up to 5-axis machining on HAAS UMC 1000

40”x25”x25” rotary table

Manual milling, drilling and tapping available

Lorem ipsum and live tooling

Up to 30″ diameter by 80″ length with 25″ swing

Up to 24″ deep bores with 6″ diameter

Manual turning available

96″ x 48″ x 4″ working area

2D and 3D tool paths

Able to stack milled sections to produce large-scale pieces up to 48” tall

At CreateProto, we are efficient at managing orders with only a few clicks, while providing top-grade custom vacuum casting services to produce urethane cast parts with precision and accuracy.

Just a few clicks and you will access quick custom quotes and orders. With our all-in-one order management and regular updates, handling the existing orders and future orders has become easier than ever!

Gone are the days of requesting multiple quotes! Even for multiple quantities for the same part, we are offering a quick and comprehensive quote so our clients can compare different prices and order as per budget

You can expect fast turnarounds for low-volume vacuum casting prototypes and part production with our quick DFM feedback. Our experts use advanced machine learning algorithms for fast design analysis.

At CreateProto, we are offering exceptional vacuum casting services for low-volume plastic prototypes, especially for small batches and fast short-run production. We strive to deliver cast urethane parts within weeks in most cases.

Our vacuum casting process cuts the need for metal tooling, especially in case of minimum quantities for short runs. This polyurethane casting technology is an effective and affordable way to create low-volume plastic prototypes.

After creating prototypes, our experts test vacuum casting parts to ensure it’s ideal for the market, like end-use functionalities and quality finishes. Also, we can incorporate changes faster for testing before the market launch.

If you need fast-run production for small batches, custom vacuum casting is an excellent option. We strive to meet on-time production affordably without compromising quality. We test the final part before the market launch.

CreateProto offers a wide range of tolerances for vacuum casting as per custom requirements. Based on the geometry complexities of the part and master pattern, we aim to reach a standard tolerance with a precision to reach ±0.05 mm.

| Type | Information |

|---|---|

| Accuracy | Highest Precision able to reach ± 0.05 mm |

| Minimum wall thickness | 1.5mm~2.5mm |

| Color and finishing | Customized options for texture and color |

| Quantities | 20 to 25 copies for each mold |

| Typical lead time | Up to a dozen of short runs within weeks |

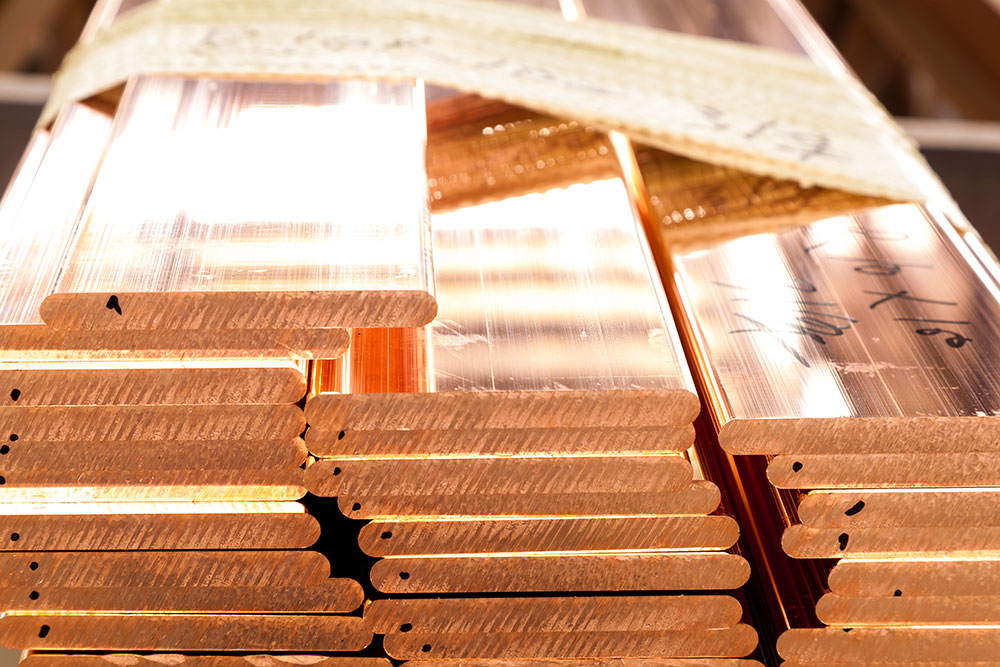

At CreateProto, we are offering a wide variety of vacuum casting materials, based on your product specifications. Here, we have grouped all the casting materials to help you make the right choice for your parts.

ABS thermoplastic is hard, rigid, and impact-resistant, making it ideal for different applications during the vacuum casting process.

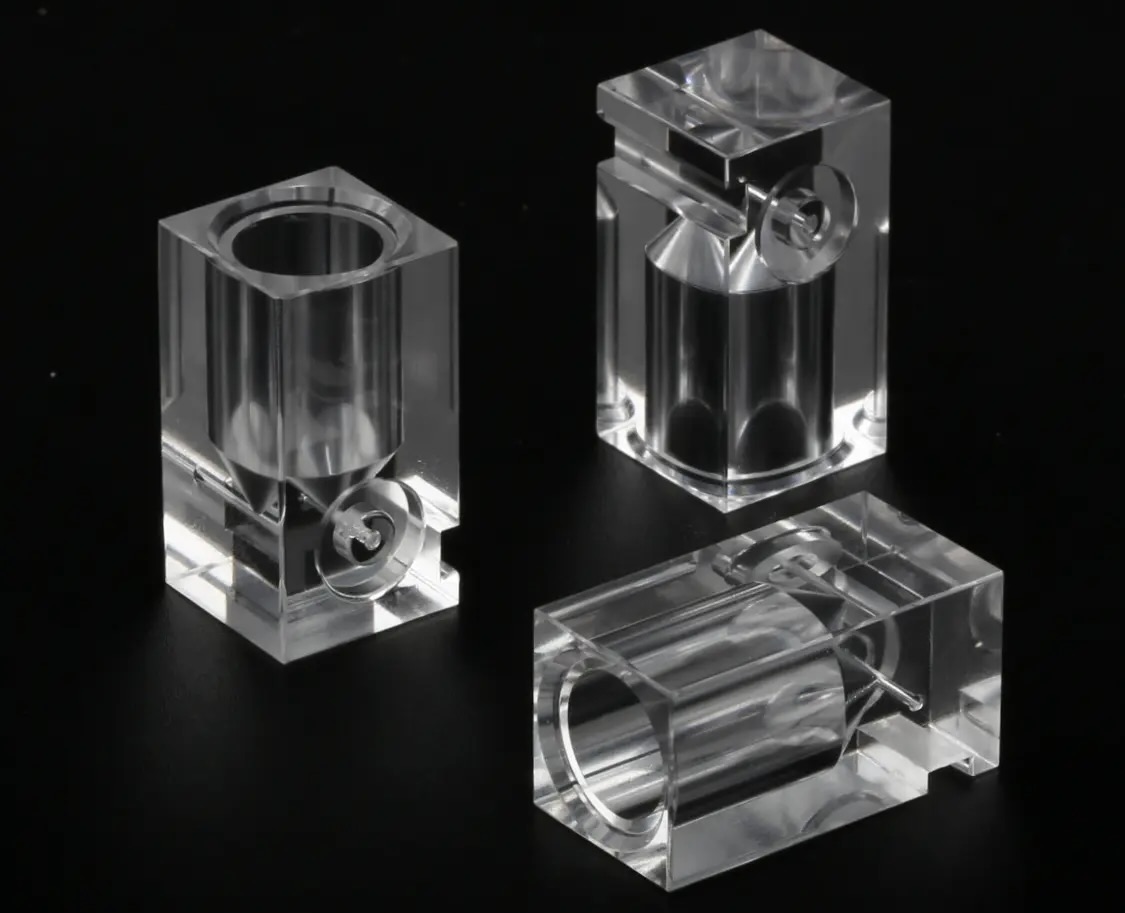

Acrylic is hard with good clarity and medium to high strength, stimulated by transparent and stiff urethane resin, an ideal material for vacuum casting see-through products.

This material is flexible, tough, and abrasion-resistant, ideal for inexpensive low-volume plastic prototype production through vacuum casting.

Polycarbonate, a rigid, clear, and high-impact material, is easy to machine and gives finishing using vacuum casting.

Want a glossy finish to your parts? This UV-stable, high-quality urethane resin comes with great clarity, ideal for producing clear parts.

It’s one of the most common materials used during vacuum casting for a variety of applications due to its ductility, strength, and machinability.

With us, you can access a wide variety of surface finishes for vacuum-casted parts. We can create unique finishes tailored to your needs to achieve the parts’ hardness, appearance, and chemical resistance.

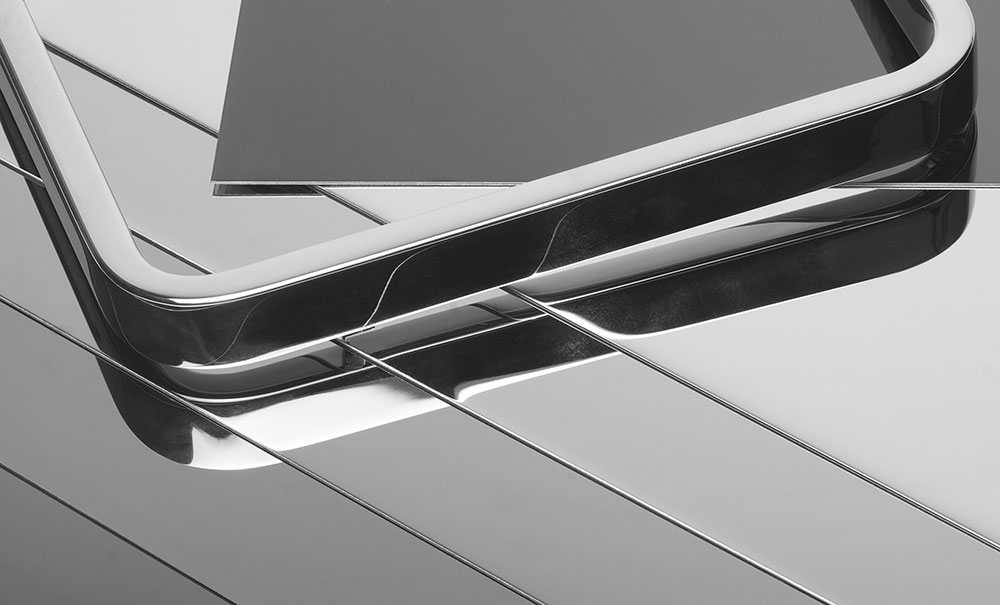

At CreateProto, we can create a highly reflective finish polishing the master pattern before we make the mold. You will get high transparency, making the parts ideal for lenses, cosmetic products, and different cleanable surfaces.

With this surface finish, you won’t get a highly reflective finish to your vacuum-casted parts but sheen effects. We use gritty sandpaper to make the surface smooth and clean to bring the finish between matte and high-gloss.

Do you want a stain-like finish to your vacuum-casted parts? We can bring that through the sand or bead blasting process of the master pattern. This finish is ideal for handheld parts and high-touch areas.

CreateProto is efficient at creating custom surface finishes with advanced technologies during vacuum casting. We strive to meet our clientele’s requests by providing unique finishes and giving the best outcomes.

At CreateProto, we strive to achieve both quality and speed to meet on-demand production using our latest tools and technologies for vacuum casting. Within weeks, you will get your vacuum cast parts delivered.

We have a wide range and variety of surface finishes for vacuum-casted parts, from high-gloss to semi-gloss to matte finish. Also, our experts offer custom finishes as per your project needs.

You want unique vacuum-casted parts but without paying more than your budget. With us, you can get a quick and accurate quote with DFM feedback just within a few hours for almost every project.

Vacuum casting is used generally for plastic prototyping for low-volume production. And, even after final production, you will get us available 24/7 for any engineering needs for master patterns if required.

It’s been two times we have worked with CreateProto, and honestly, they have never disappointed us. We just requested the quote, and they have handled the rest, from product design to production to testing and launch- All the fulfillment required for our projects so far. Professionalism and convenience- Perfect reasons to work with them!

Avram Mckinney Mechanical Engineer Associate, Thermaco

It’s really impressive working with CreateProto for our automotive projects. Quick responses all the time that has eased communication. We don’t have to manage or juggle suppliers. They got us all covered! In fact, their prices are too competitive, even for mass customization and low-volume production.

Timothy Frederick CAE Mechanical Engineer, BirdCreateproto serves a wide range of sectors such as medical, automotive, electronics, and aerospace, offering inclusive prototyping solutions that drive innovation and uphold standards of excellence

The minimum thickness for vacuum casting is 0.75 mm, but for the best results, we recommend 1 mm to avoid shrinkage and wrapping. With thicker walls, you will get more support for your vacuum-casted parts.

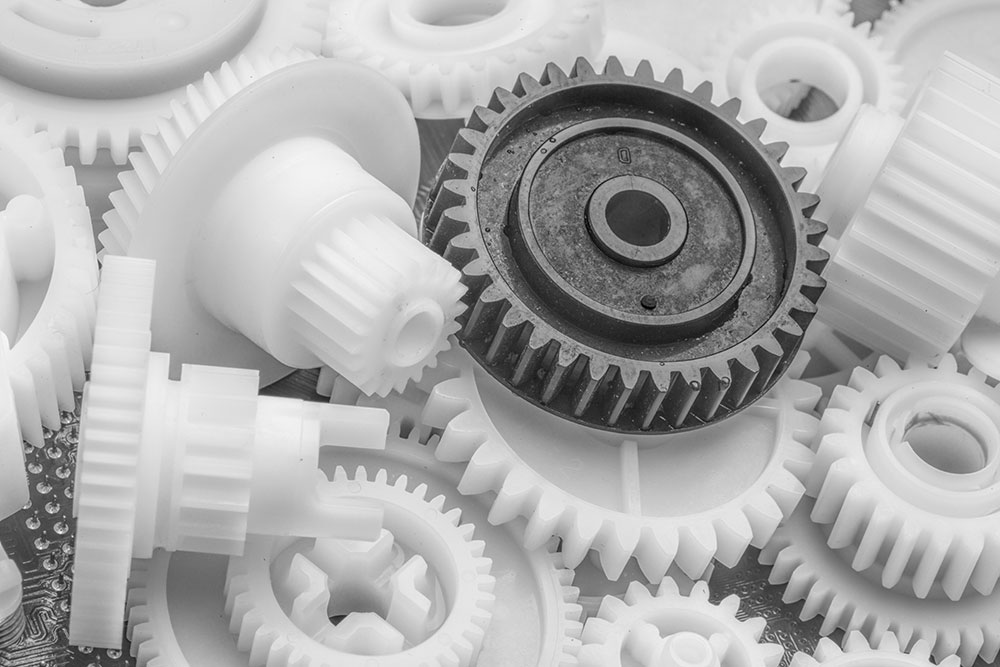

Vacuum casting is an ideal process to create plastic and rubber parts for low-volume production, prototypes, and end-use parts. It’s best suited to design complex parts with intricate features and thin walls with accuracy and smooth surface finish.

During the vacuum casting process, we use mold clamps, vacuum pressure, and mold release agents to keep the mold together. For more complicated parts, our experts take additional measures, like bolts and screws.

At CreateProto, we use different materials for vacuum casting, from thermoplastics to resins to rubbers. It depends on the casting properties you desire for your product. For example, ABS or polycarbonate is used for durable and strong casting, while rubber is for flexible casting.

Whenever and whatever we have needed, Createproto has delivered every time with the exact precision and quality required. Faster turnarounds, perfect finish, and on-time delivery for product launch- Great experience working with them. We appreciate their professionalism and are looking forward to teaming up with them again.

Tyler Richards Lead Mechanical Engineer, Shimano