Over the years, the demands for part production in the automotive, medical, and aerospace industries. And, to meet the incredible versatility and complexity of the part designs, aluminum is the most preferred material choice among CNC machining manufacturers. After all, aluminum CNC machining speeds up the part design and manufacturing three to four times compared to other materials, like titanium or steel. Thanks to its impressive flexibility and strength-to-weight ratio!

Moreover, automobile and aircraft industries choose aluminum for internal structure and component design and manufacturing for its lightweight feature and fuel efficiency. Also, its sleek and silver finish makes it best for electronic devices as well.

But, being a newbie in this field, you may wonder what this CNC aluminum machining is, what types of steel are used here, and much more. Well, all your answers are in today’s guide. So, keep reading!

What is an Aluminum CNC Machining?

Aluminum CNC machining is a process combining a computer numerical control (CNC) system and traditional manufacturing techniques. The development of CNC machines happens after the invention of computers in the 1960s. It cuts and shapes solid materials into complex designs, which are usually time-consuming and nearly impossible if following the manual processes. As a result, aluminum CNC machining parts are designed with high precision and accuracy, while allowing you design freedom, faster production, and consistency with less waste. The most common CNC machines used for part and component manufacturing for aircraft, medical, and automotive sectors are drilling and 3 and 5-axis milling machines, lathes, CNC turning, and routing.

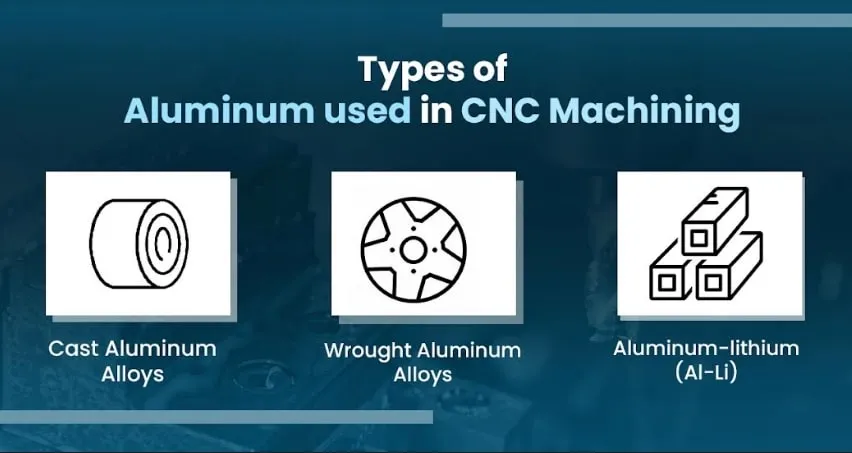

Types of Aluminum used in CNC Machining

If used in the purest form aluminum is corrosion-resistant and malleable, while serving as an excellent heat and electricity conductor. However, it is weak for direct commercial applications. That’s why manufacturers often create alloys by mixing other elements, like copper, zinc, silicon, or lithium, with molten aluminum to achieve strength for CNC machined parts and boost their natural properties. Here are some most common alloys used in CNC aluminum machining:

- Cast aluminum alloys, where molten aluminum is shaped by pouring into a mold (as the shape needed for the part design) and cooled- An affordable and durable choice in the automotive industries

- Wrought aluminum alloys, where aluminum is shaped in its solid state after transforming liquid aluminum into large blocks and rolled or cut to give the shape using CNC machining tools

- Aluminum-lithium (Al-Li) alloys are mostly used in aerospace sectors in making inner wing structures, lower wing skins, fan blades, and fuselages, as lithium is lighter than pure aluminum. Also, in space rockets and racing cars, the uses of Al-Li alloys are found.

Aluminum CNC Machining or Steel Machining: Which Is Better?

When it comes to CNC machining, aluminum, and steel are the most widely used materials to create CNC machined parts for commercial applications in various sectors, from medical to aerospace to automotive. But, which one is right for your part production depends on considering the following factors:

Corrosion resistance

Speaking of rust and corrosion, both stainless steel and aluminum are highly resistant to them. But, steel is a more expensive option compared to aluminum as it needs coating and painting to protect it so the final machined parts don’t get exposed to harsh elements. Also, steel needs quite maintenance, which costs further. So, if you are likely to maintain a limited budget, go for the aluminum option.

Costs

Aluminum alloys are a little more expensive than carbon and mild steel, while stainless steel costs more. In short, you need to look at the durability of the materials so you can save in the long term. On the other hand, the metal costs vary depending on the global demand.

Weight

Compared to stainless steel, aluminum is three times lighter, making it best for creating lightweight parts, like aircraft and automotive components. Incorporating lighter materials ensures better product performance. Also, aluminum is easy to machine, three to four times faster, as it is less dense than steel.

Choose the right one based on what kind of components you want to make and how much you can spend.

In Conclusion

Now, if you are looking for a reliable aluminum CNC machining service, count on us. At Createproto Rapid System Limited, we are offering top-notch and high-quality CNC aluminum services for automobile, aerospace, and medical sectors to create complex machined parts with accuracy and precision. Contact us now and get a FREE quote today just within a few hours!

Follow us on Instagram for more information