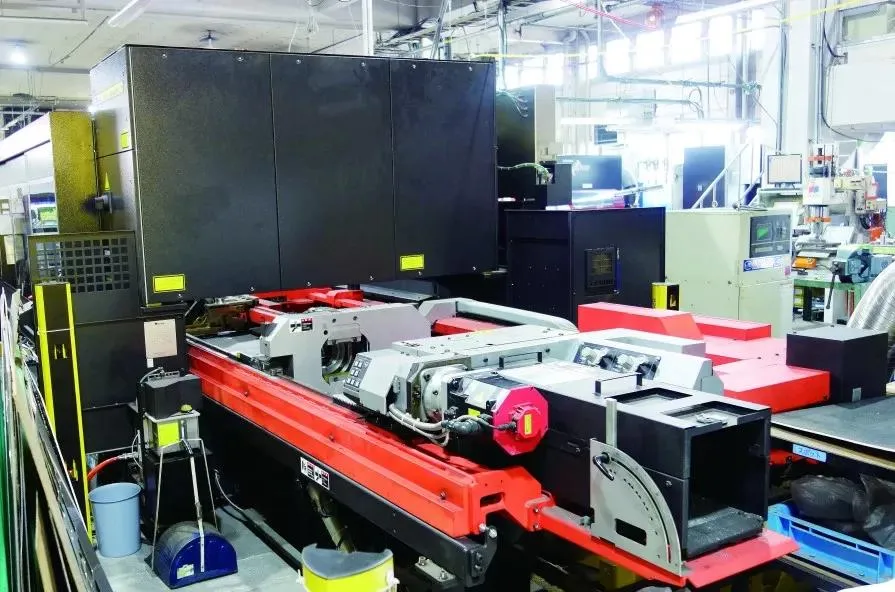

Laser cutting machine FO-MⅡ RI3015 for both flat and pipe fittings

Focus on precision sheet metal processing and precision machining

Createproto focusing on precision sheet metal processing and precision machining, we are committed to the production of mechanical parts related to semiconductor manufacturing equipment and measuring instruments, as well as sheet metal parts for medical equipment.

Take matching orders for machined parts and sheet metal parts

As the main business in the past, stamping and mold making businesses are shrinking, and the machining factories that once engaged in mold making have been transformed into precision machining parts factories. By accepting matching orders for machined parts and sheet metal parts, we have expanded the processing field and successfully opened up new customers, led by medical equipment.

“Demands are constantly changing, and customers require us to produce higher-precision and higher-quality products in a shorter period of time. To this end, we are working hard to make use of the accumulated processing skills, skilled operators, and the most advanced Equipment to quickly respond to customer requirements”

Bending machine with automatic die changing device

Provide solutions to create value for customer service and build a relationship of trust

The semiconductor industry undergoes a business change called the silicon cycle approximately every four years. Due to the fast pace of technological innovation and difficult equipment investment, huge changes will occur when semiconductor products are updated.

“Therefore, while we are working hard to increase the business of equipment manufacturers with different manufacturing processes, we have also strengthened business activities and opened up new industries such as switching power supply devices, measuring instruments, medical equipment, and food machinery. It is particularly worth mentioning. Yes, we have proposed a comprehensive VE solution for precision machining and precision sheet metal processing, as well as Q, C, D strategies for multi-variety and small-batch production, etc., and persistently provide customers with value-creating proposals. Through these measures, we I hope to establish a relationship of trust with customers, so that more customers can rest assured that the entire business from design to assembly will be handed over to us.”

“Semiconductor manufacturing equipment, medical equipment, and food machinery mostly use stainless steel. Now we receive about 4,000 (about 30,000) orders from different customers every month. Repeat orders account for more than 50%, and nearly 10% are within a week. Short delivery time products. In order to meet the needs of these customers, we have promoted measures such as’introducing the latest equipment’,’sharing manufacturing skills’, and’improving efficiency through a self-developed management system’.

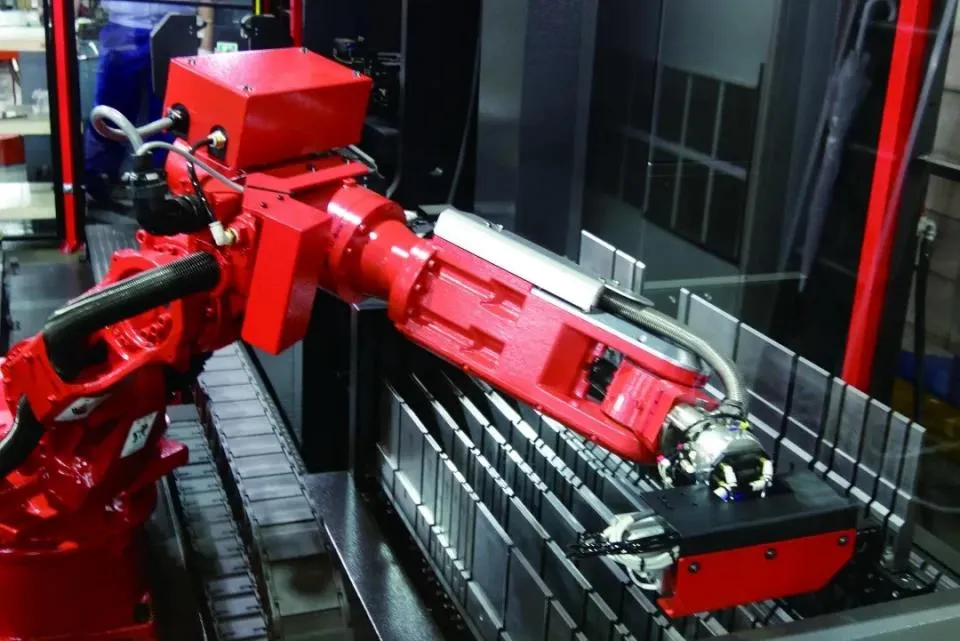

“Now our products use materials: 70% stainless steel (plate thickness 0.5-6.0mm), aluminum 20% (plate thickness 0.8-5.0mm), copper and brass 10%. In order to deal with the problem of welding distortion, we have equipped Six laser welding machines with various characteristics can provide welding solutions suitable for materials. This is the key to our company’s proposal.”

Fiber laser welding robot FLW-4000