Imagine you’re an entrepreneur, carefully designing complex parts for another line of high-precision clinical gadgets. You’ve put hours into perfecting the design, yet with regard to production, finding a machining process that can deliver the accuracy and quality you want seems to be overwhelming. This was the exact challenge faced by a client of CreateProto a few months ago.

They required small, complex parts with tight tolerances and flawless surface finishes — anything less could compromise the entire product’s usefulness. After considering various manufacturing options, they turned to our Swiss CNC machining services. The results? Flawless components delivered ahead of schedule, with production costs lower than anticipated.

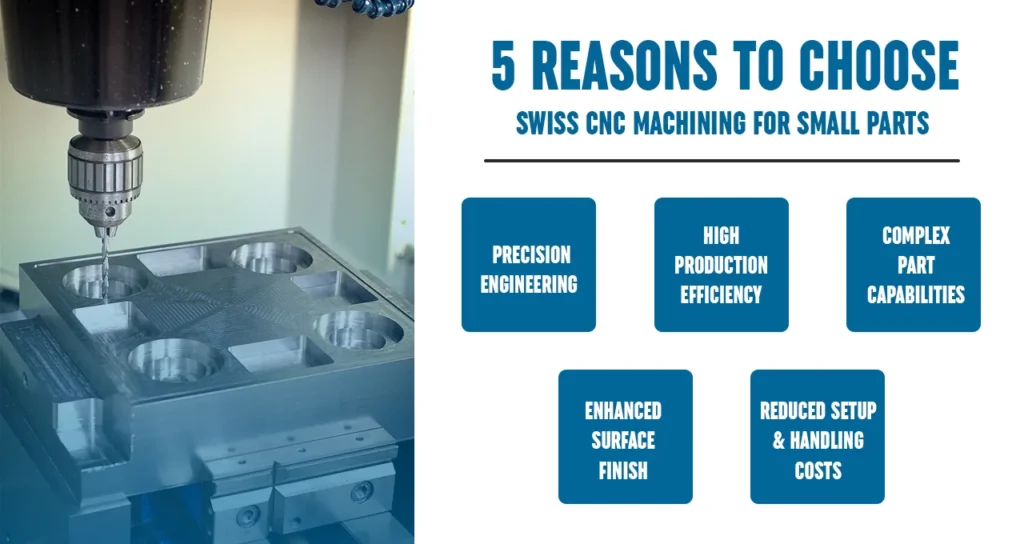

If you’re in a similar situation, here are five compelling reasons why Swiss CNC machining could be your perfect solution.

Reason 1. Precision Engineering:

Precision is non-negotiable with regard to small parts, particularly in ventures like aviation, clinical, and electronics, where even a minor deviation can prompt critical issues. Swiss CNC machining is prestigious for its capacity to create parts with unquestionably tight resistances, frequently within ±0.001 inches.

This degree of accuracy is accomplished through the machine’s plan, which permits the workpiece to draw nearer to the cutting instrument, lessening redirection and guaranteeing precision. In general, parts made using Swiss CNC machines show 20% higher accuracy than those made with conventional CNC machines.

Reason 2. High Production Efficiency:

Time is money, particularly in manufacturing. Swiss CNC machines are intended to amplify productivity by performing various activities simultaneously. For example, while one apparatus is cutting, another can be working at drilling or finishing. This concurrent processing essentially reduces process durations.

Moreover, Swiss CNC machining can decrease production times by up to 30% compared with conventional CNC strategies. This implies quicker completion times for your projects, assisting you with fulfilling tight time without compromising on quality.

Reason 3. Complex Part Capabilities:

Creating small parts with complex geometries can be challenging with ordinary machining techniques. In any case, Swiss CNC machining excels around here, because of its multi-axis abilities. With 4-axis and 5-axis machining, the device can move toward the workpiece from different angles, making it possible to make complex designs in a single setup.

This capacity is especially useful for businesses requiring definite parts, like the clinical device sector, where parts frequently include complex shapes and tight internal passages. As a matter of fact, Swiss CNC machining is frequently the go-to method for delivering parts like bone screws, dental implants, and microelectronics.

Reason 4. Reduced Setup and Handling Costs:

Conventional machining techniques frequently require numerous arrangements and handling, which increases production time and raises costs. Swiss CNC machining, on the contrary, integrates several operations into a single setup, limiting the requirement for additional handling.

This reduction in setup and handling speeds up the production process and also cuts down on labor costs. Organizations involving Swiss CNC machining report a 15% decrease in production costs.

Reason 5. Enhanced Surface Finish:

The surface completion of a part can be essentially as significant as its dimensional accuracy, particularly in applications where style and usefulness are crucial. Swiss CNC machining is known for creating parts with superior surface finishes and dispensing them with the requirement for extra completing cycles.

This top-notch finish is accomplished through the machine’s capacity to keep up with tight control over cutting conditions, combined with the utilization of high-grade raw components.

Bottom Lines:

For precision manufacturing, the selection of the machining cycle can make or break your project. Swiss CNC machining offers unrivaled accuracy, effectiveness, and flexibility, making it the best decision for the production of small, complex parts.

Whether you want a rapid prototype or a production run, we’re here to assist you. Reach out to us today for an instant quote and see how our experts can bring your designs to life with precision and efficiency.