When you think about the military, you might picture soldiers in uniform or advanced weapons. But there’s another essential part that often goes unnoticed: CNC machining. This technology is crucial for creating many military components, ensuring they are precise, reliable, and ready for action.

Let’s dive into the world of CNC machining and discover its key applications in the military and defense industries.

What is CNC Machining?

CNC stands for Computer Numerical Control. It’s a cutting-edge technology machine that is controlled by computers to make parts with incredible accuracy. Imagine a robot that can cut, drill, or shape materials based on a computer program. That’s what CNC machining does! It can work with metals, plastics, and other materials, making it super versatile for different projects.

Advantages of Using CNC Machining in the Military and Defense Sector:

So, why are applications of CNC machining so popular in the military and defense sectors? The following are some of the advantages-

- Consistency and Precision: CNC machines can make parts that are the same every time. In the military, even a tiny mistake can be a big problem. That’s why precision is crucial.

- Customization: The military often needs unique parts for new weapons or equipment. CNC machining can create those custom parts quickly.

- Efficiency and Speed: CNC machining can produce parts faster than traditional methods. This means the military can get what it needs without long delays.

- Cost-Effectiveness: With less waste and quicker production times, CNC machining helps save money, which is always a plus!

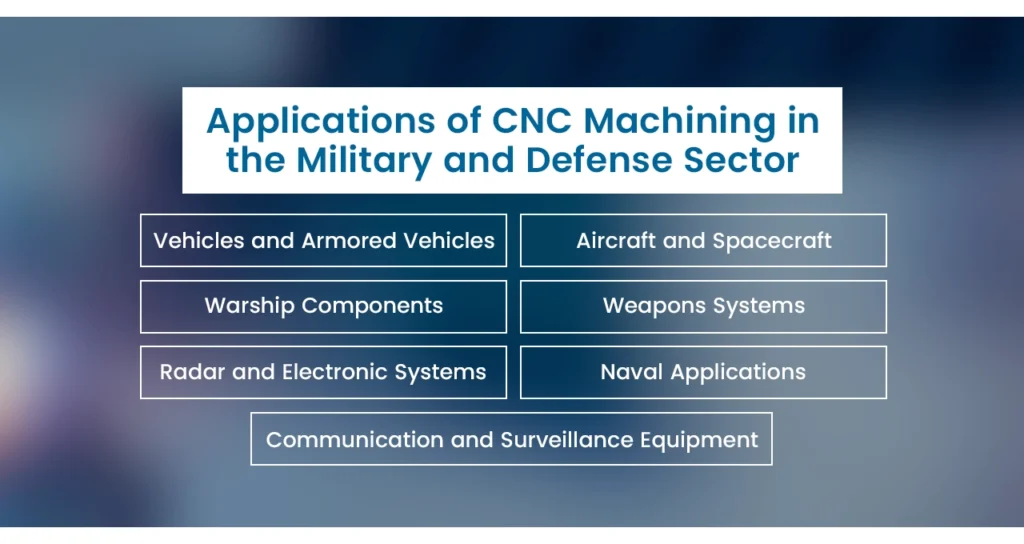

Applications of CNC Machining in the Military and Defense Sector:

For the military and defense sectors, CNC machining is very important. Let’s have a look at some of the prime applications of this technology-

- Aircraft and Spacecraft: Flight and space present challenging environments that necessitate components capable of enduring extreme temperatures, vibrations, and pressures. CNC machining provides the means to produce parts like wings, engines, landing gear, and elements of spacecraft with extraordinary accuracy and lasting quality.

- Weapons Systems: The functioning of weapons systems is reliant on the precision and consistency of their parts. With CNC machining, we can manufacture components for firearms, missiles, bombs and other kinds of weaponry with precise measurements maintained strictly, this guarantees supreme operation capability.

- Naval Applications: The marine environment presents special hardships for apparatus, necessitating parts that can resist rust and endure the tough situations in the sea. CNC machining gets employed to make parts for submarines, boats, and marine craft guaranteeing their reliability as well as long lifespan.

- Communication and Surveillance Equipment: Today’s war techniques greatly depend on improved communication and surveillance technologies. The making of parts for drones, radar systems, and satellites highly requires CNC machining to guarantee their accuracy and efficiency in important tasks.

- Vehicles and Armored Vehicles: Land troops depend on many kinds of vehicles such as tanks, armored personnel carriers and support vehicles. CNC machining is utilized to make parts for these vehicles, making sure they are durable, mobile and protected.

- Radar and Electronic Systems: Radar and electronic systems are very important for detecting and tracking threats. CNC machining is used to make parts like antennas, circuit boards, and other essential pieces so these systems can work accurately and dependably.

- Warship Components: Current war vessels are complicated systems that need a variety of parts. CNC processing is applied to make pieces for driving mechanisms, communicating tools, arms systems and other essential components. This guarantees the warship’s preparedness for any task.

Bottom Lines:

At CreateProto, we excel in CNC machining for the military and defense world. Our skilled team works hard to make parts that are really high quality and better than what’s expected. We understand the unique challenges and demands of the defense sector, including stringent specifications, tight tolerances, and often critical timelines.

So, why wait? Reach out to us now and get an instant quote for your project today!