Die casting ranks high on the list of important metalworking processes. As with other forms of casting, molten metal is poured into a two-piece mold, but die casting does so under pressure, forcing the material into every nook and cranny of the cavity within. This means that die cast parts are typically very accurate. The technology is able to create net or near net shapes even where complex geometries are involved, with smooth surfaces to boot. This means very little secondary machining is required, further reducing costs. And because the process is quite fast relative to traditional casting methods, it’s a darling of high-volume manufacturers such as automakers and those making consumer products.

The Matchbox cars and Monopoly game pieces you might have played with as a kid are die cast. So are most engine blocks, transmission housings, cylinder heads, and alternator bodies. Beyond the automotive sector, many plumbing components are die cast, as are laptop computer frames, toaster and blender bases, along with a whole slug of components for the medical, communication, electrical, and firearm industries. Die cast parts are everywhere.

Most such parts are made of “white metals” such as zinc, aluminum, or magnesium, although copper and bronze can also be die cast. Ferrous materials like iron and steel, on the other hand, are found in traditional mold-based casting processes. White metals are preferred for their low melting points, corrosion resistance, and high strength to weight ratios, making them ideal for applications where light weight is a priority.

HOT OR COLD?

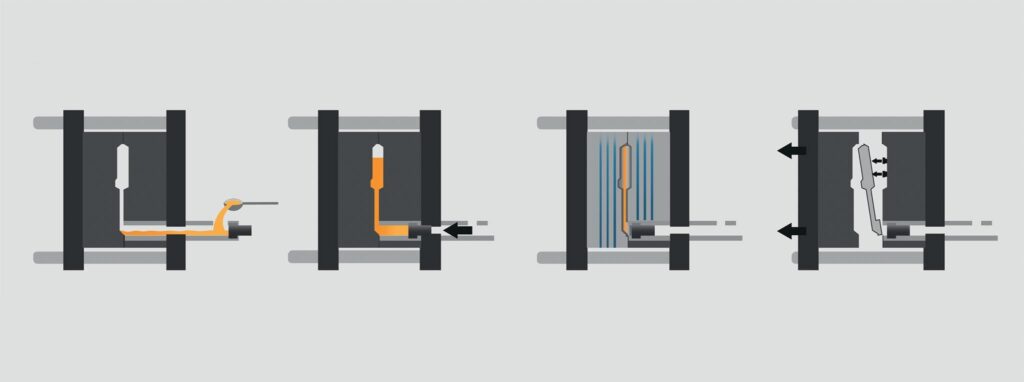

There are two primary types of die casting in use today. As its name implies, a hot chamber die casting machine contains a heated chamber filled with molten metal, inside of which sits a cylinder and piston mechanism. At the start of the casting process, the piston retracts, opening a port that allows metal to fill the cylinder. This “shot” is then forced through a valve and into the die cavity. After a brief pause to allow the metal to solidify, the die halves separate, the part is removed, and the process is repeated. Hot chamber die casting is most often used with zinc and magnesium due to their lower melting points.

Cold chamber die casting machines, on the other hand, rely on a ladle to fill the cylinder with molten material. This additional step makes it slower than hot chamber die casting, but because the injection mechanism is not constantly immersed in extremely hot liquid metal, cold chamber machines support the casting of aluminum and other metals with higher melting temperatures. There are also a number of variants and proprietary systems available, such as low-pressure and vacuum die casting, squeeze casting, and die casting using multiple slides for high complexity parts.

BEYOND THE DIE

Several die casting caveats exist. For starters, secondary operations are usually required to finish die cast parts. Holes must be drilled and tapped, and critical surfaces milled or turned. Belt sanding might be needed to “deflash” die cast parts, although depending on part complexity and quantity, a trim die can also be used to shear away any excess material in a single operation. Vibratory deburring or rotary tumbling is also common for smaller parts, helping to smooth rough edges. The latter, however, is often unnecessary—most die cast parts exhibit excellent surface quality. And like practically any metal part, those produced with die casting are suitable for plating, painting, anodizing, or coating to increase corrosion resistance or make them more pleasing to the eye. Note the term “deflash” just mentioned. As discussed earlier, the tool used to make die cast parts—the die, sometimes referred to as a mold—is constructed of two halves, and contains runners and sprues through which the molten material flows. When the casting cycle ends, the die’s movable half retracts, and ejector pins within force the finished part and its attached runners from the die. These must be removed and the adjoining surfaces smoothed, usually with a trim die or even a hand tool to cut away the runners before sanding the rough edges with an abrasive belt.Deflashing aside, even the most perfectly machined die surfaces can allow some small amount of material to escape between the two when subjected to the intense pressures of the die casting process. These are called parting lines. The same phenomena occur with cast metal parts and ones made using plastic injection molding, but as with die casting, all can be minimized through the use of a well-designed, high-quality die and proper application of casting parameters such as metal temperature, pressure, and flow. Whatever the process, parting lines are common and must be removed using mechanical means if cosmetics are important.

THE DFM DANCE

Die cast part design is just as important as the tool. Part surfaces running parallel to the direction of die opening require draft angles of a few degrees to support part ejection. Die cast parts can contain undercuts, but these features will require the use of cores or movable slides, driving up tooling cost. Wall sections should be as uniform as possible to reduce warpage caused by uneven cooling. Sharp corners should be avoided where possible, and ribs should be used to support tall, narrow features like heat sinks. High-quality tooling is critical to the success of any die casting application.