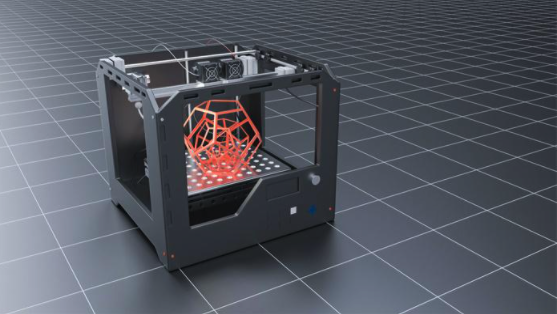

3D printing technology is also called additive manufacturing technology, which is based on digital model files, using powdered metal or plastic and other bondable materials to construct objects by printing layer by layer. 3D printing is usually achieved by using digital technology material printers. In the past, it was often used to make models in mold manufacturing, industrial design and other fields. Now it is gradually being used in the direct manufacturing of some products. Some companies have begun to use this technology to print parts. The technology has applications in jewelry, footwear, industrial design, architecture, engineering and construction, automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, guns, and other fields.

3D printing technology is based on the computer three-dimensional design model, through the software layered discrete and numerical control molding system, using laser beams, hot melt nozzles and other methods to stack and bond special materials such as metal powder, ceramic powder, plastic, and cell tissue layer by layer. , And finally superimposed to form a physical product.

3D printing materials:

Photosensitive resin materials: Mainly including light-curing resin materials such as acrylic resin, epoxy resin and polyester resin. Such materials can undergo polymerization reaction and solidify under the irradiation of ultraviolet light, and generally assume a liquid state. It can be used to manufacture structural parts such as blades and gears for aerospace.

Engineering plastic materials: Mainly including ABS materials, polycarbonate materials and polyamide materials. ABS materials have the characteristics of “toughness, rigidity, rigidity” and so on, so they have been widely used in machinery, electrical, textile, automobile, aircraft, ship and other manufacturing industries and chemical industries. Polycarbonate material has good impact resistance, thermal distortion resistance, good fire resistance and high hardness, so it is suitable for the production of various parts of cars and light trucks, mainly in lighting systems, instrument panels, heating plates, and defrosting And bumpers. Polyamide material, also known as nylon material, has the characteristics of toughness, wear resistance, self-lubrication, and wide applicable temperature range. It mainly replaces copper and other non-ferrous metals to manufacture mechanical, chemical, and electrical parts, such as diesel engine fuel pump gears and water pumps. , High-pressure sealing ring, oil pipeline, etc.

Metal materials: Mainly include titanium alloy materials, stainless steel materials, aluminum alloy materials, and other precious metal materials. Titanium alloy materials have high strength and high heat resistance. Compared with other metals, titanium alloy also has the advantages of good corrosion resistance, good low temperature performance, and high chemical activity. Therefore, it is widely used in the production of aircraft engine compressor parts, rockets, missiles and high-speed aircraft structural parts. Stainless steel materials have the advantages of easy welding, corrosion resistance, strong polishing and heat resistance, and are widely used in the fields of construction, food processing, catering, brewing, chemical and medical equipment. Aluminum alloy materials have the characteristics of low density, low melting point, and strong plasticity. Aluminum alloy is currently the most widely used alloy and is widely used in aviation, aerospace, automobile, machinery manufacturing, shipbuilding and chemical industries. Other precious metal materials, such as gold materials, have the characteristics of good electrical conductivity, good thermal conductivity, and high stability. They are mainly used in the fields of electronics, chemical industry, aerospace and other fields that have special requirements for materials.

Ceramic materials: Mainly including clay, kaolin and other natural silicate materials and high-purity synthetic materials such as oxide ceramic materials, nitride ceramic materials, carbide ceramic materials, etc. Since most of the ceramic materials have a high melting point or even no melting point, it is difficult to use external energy for direct forming. Most of them require reprocessing (drying, sintering, etc.) after forming to obtain the final product, which limits the use of ceramic materials in the 3D printing industry. Promotion. However, ceramic materials have the advantages of high hardness, high temperature resistance, and stable physical and chemical properties that polymer and metal materials do not possess. Therefore, they have broad application prospects in aerospace, electronics, automobiles, energy, biomedical and other industries.

Biomaterials: Mainly include biomedical metal materials, biomedical polymer materials, biomedical ceramic materials and bio-derived materials. Among them, bio-derived materials are biomedical materials formed from natural biological tissues that have undergone special treatment, and are also called bio-renewable materials. The application of biomaterials in 3D printing can be divided into two areas. The first category is the application of biomaterials to food processing, food packaging and other fields based on the characteristics of biodegradability, low melting point, biological characteristics, and environmental protection; Based on the reproducibility, histocompatibility and inducibility of biomaterials, mechanical compliance and degradation compliance, it is widely used in the medical field. The application of biomaterials in the medical field can be divided into the manufacture of prostheses, and the three-dimensional indirect cell There are three levels of assembly manufacturing and cell three-dimensional direct manufacturing.

Rubber materials: Rubber materials have a variety of elastic material characteristics, such as Shore A hardness, elongation at break, tear resistance and tensile strength, making it very suitable for applications that require non-slip or soft surfaces Areas, such as consumer electronics, medical equipment, and automotive interiors.

Sand and gravel materials: Mainly quartz sand. In 3D printing, according to its traditional functions and characteristics, sand and gravel materials are mainly used in construction to make some building materials or structures. Low cost, high efficiency and environmental protection are the advantages of sand and gravel materials in the field of 3D printing construction.

Graphene materia: Craphene is a new material with sp ² hybrid connected carbon atoms tightly packed into a single-layer two-dimensional honeycomb lattice structure. Graphene materials have excellent optical, electrical, and mechanical properties, which can be used to replace various traditional materials and are considered to be a revolutionary material in the future. With the development of graphene preparation level and the development of graphene application technology, graphene materials can be applied to more downstream products and fields. According to the estimates of the Chinese Academy of Sciences, by 2024, graphene devices are expected to replace complementary metal oxide semiconductor devices and be applied in research fields such as nanoelectronic devices, photoelectrochemical cells, and ultralight aircraft materials.

Cellulosic materials: Which are macromolecular polysaccharides composed of glucose, are insoluble in water and general organic solvents. Cellulose is the main component of plant cell walls. It is the most widely distributed and most abundant polysaccharide in nature, accounting for more than 50% of the carbon content of the plant kingdom. Researchers have been working on developing methods for 3D printing using cellulose, and there have been some breakthroughs. Cellulosic materials still have some shortcomings, such as their high cost, poor scalability, and contaminants when combined with plastics.