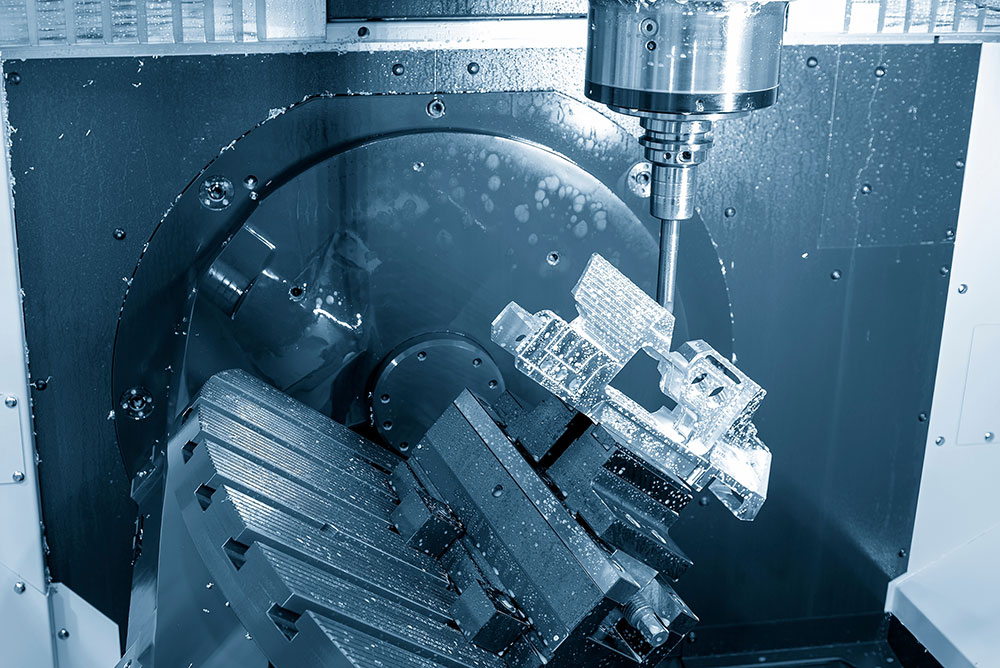

CreateProto provides CNC machining for the aerospace sector with advanced prototyping solutions, streamlining processes for heightened efficiency. Empowering manufacturers, it accelerates innovation and ensures the swift delivery of high-quality aerospace components to the market.

CreateProto pioneers aerospace prototyping and manufacturing through advanced engineering, state-of-the-art technology, and a dedication to excellence, guaranteeing swift progress and successful production outcomes

Createproto guarantees adherence to aerospace industry standards, delivering precision and durability in aircraft components. Utilizing advanced manufacturing methodologies, we produce high-quality, dependable parts capable of withstanding stringent aerospace requirements.

Simplifying procedures, Createproto offers prompt and precise quotations, accelerating decision-making in aerospace component manufacturing. This enables clients to proceed smoothly with confidence and operational efficiency.

Providing customized solutions, Createproto caters to varied aerospace requirements. Whether it's materials or intricate design specifications, our customization options empower clients to optimize components for specific applications, thereby enhancing overall product performance.

Createproto delivers instant aerospace solutions through agile approaches and advanced technology, ensuring swift issue resolution. Our rapid response and adaptive strategies meet the industry's dynamic demands with seamless efficiency.

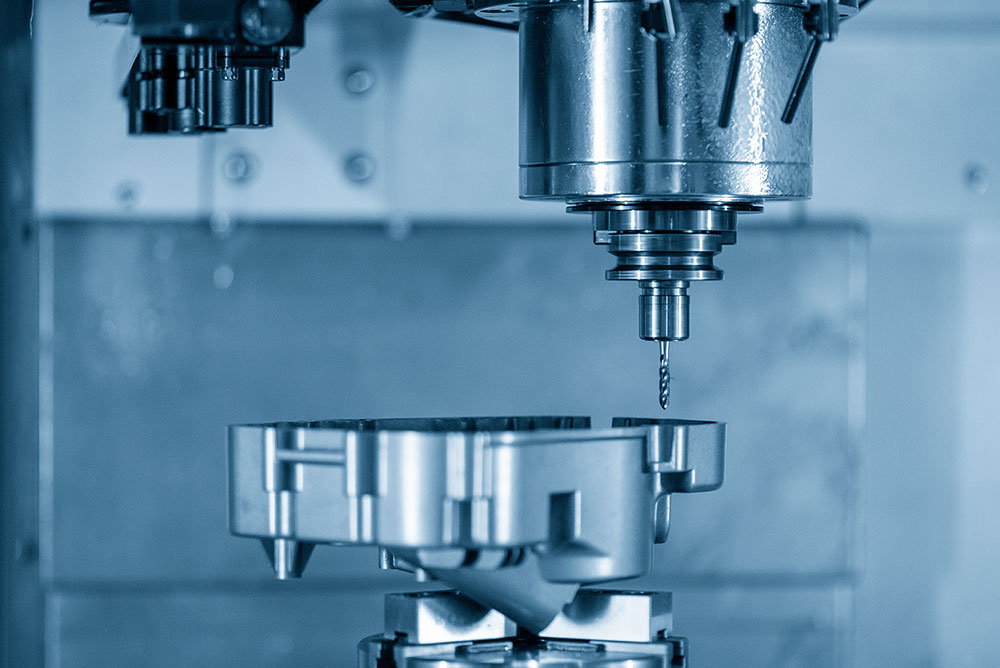

CreateProto’s aerospace specialists excel in precision CNC machining, delivering high-quality components that meet industry standards. Leveraging advanced technology and extensive engineering expertise, we offer tailored solutions to address unique aerospace requirements. From rapid prototyping to full-scale production, our commitment to excellence accelerates innovation, enabling aerospace manufacturers to achieve their goals with efficiency and reliability in this dynamic and demanding industry.

CreateProto’s aerospace specialists provide precision through high-quality CNC machining, psreenting customized solutions that expedite innovation and guarantee top-tier performance in aerospace component manufacturing.

Dive into the dynamic realm of aerospace prototyping with CreateProto, where precision converges with innovation, sculpting the future of high-performance and dependable aerospace components.

CreateProto in the aerospace industry employs a meticulous prototyping process involving design conceptualization, computer-aided modeling, and precision manufacturing. Initial ideas are translated into digital models, scrutinized for aerodynamic efficiency and structural integrity. Subsequently, advanced manufacturing techniques, such as 3D printing and CNC machining, bring these designs to life for rigorous testing, ensuring the production of high-performance and reliable aerospace components.

Discover CreateProto’s precise design testing tailored for aerospace, ensuring components meet rigorous standards in precision, durability, and performance, embodying excellence in the aviation sector.

At this stage, we will help you create prototypes according to your product’s requirements and design files. Depending on your needs, we will use low-cost materials and processes to develop parts similar to the final product. This allows you to examine the specification metrics and functional testing. Our advanced technologies also help us ensure the rapid turnaround of these prototypes.

Immerse yourself in CreateProto’s Aerospace Engineering Processing Testing—a meticulous stage guaranteeing that aerospace components align with the highest engineering standards, ensuring optimal functionality and performance excellence.

CreateProto’s Aerospace Engineering Processing Testing is a meticulous phase encompassing comprehensive evaluations of aerospace components. Advanced engineering standards guide the scrutiny, ensuring optimal functionality and reliability. Rigorous simulations assess aerodynamic efficiency, and precision machining parts testing in diverse conditions guarantees performance excellence. The iterative refinement process, based on test results, ensures that aerospace components meet and exceed the stringent engineering criteria, setting a benchmark for quality and functionality in the aerospace industry.

Discover CreateProto’s Aerospace production testing, an essential stage where aerospace components undergo thorough examination to ensure quality, reliability, and optimal performance in large-scale manufacturing.

CreateProto employs rigorous aerospace production testing processes to ensure top-tier quality. This involves comprehensive examinations of components, assessing materials, structural integrity, and performance under simulated conditions. Precision testing methods verify reliability and adherence to industry standards. The meticulous approach guarantees that aerospace parts meet stringent criteria, fostering confidence in their durability and optimal functioning in mass production.

Explore CreateProto’s final Aerospace production phase, where exacting precision and stringent quality control seamlessly unite to produce flawless aerospace components that surpass the most rigorous industry standards.

CreateProto’s aerospace final production processes epitomize precision and excellence. The meticulous assembly involves cutting-edge technologies, ensuring each component aligns with stringent industry specifications. Rigorous quality checks assess structural integrity, materials, and performance, guaranteeing that aerospace components surpass industry standards. This culmination of precision engineering and quality control ensures Createproto delivers impeccable aerospace products, meeting the highest benchmarks in the industry.

Createproto specializes in precision engineering of aircraft structural components, ensuring optimal strength and durability to meet stringent safety standards, critical for top-tier aerospace applications.

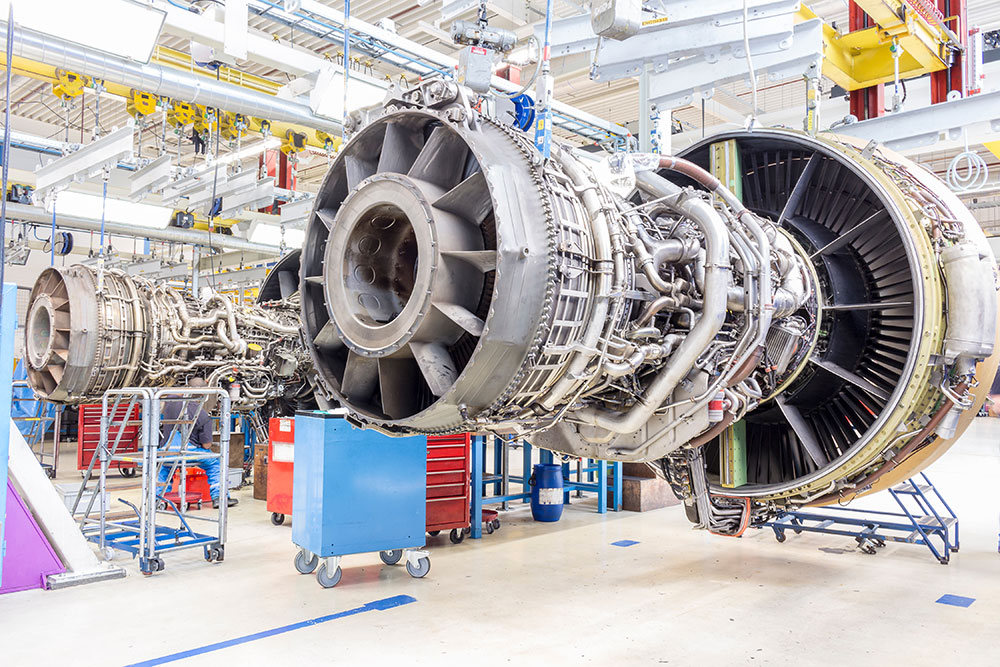

Leveraging advanced manufacturing, Createproto delivers engine parts with precision and reliability, meeting the demanding specifications of Fortune 600+ corporations for efficient and high-performance aerospace engines.

Createproto's expertise extends to landing gear systems, providing top Fortune corporations with robust and meticulously crafted components, crucial for ensuring safe and controlled landings in diverse aerospace scenarios.

Offering innovative solutions, Createproto excels in the production of avionics housing and mounting components. These precision-engineered parts contribute to the seamless integration and protection of critical avionics systems in aircraft.

Aluminum is highly esteemed for its lightweight composition and corrosion resistance, proving pivotal in enhancing both fuel efficiency and the structural robustness of aircraft.

Stainless steel is indispensable in aerospace applications, providing exceptional strength, corrosion resistance, and durability. Its high-performance characteristics make it crucial for manufacturing components that endure extreme conditions and ensure safety.

Liquid Silicone Rubber (LSR), a flexible elastomer renowned for its heat resistance, flexibility, and biocompatibility, stands as a preferred material for various applications, including aerospace, medical, and electronics industries.

Anodizing enhances aerospace parts by forming a protective oxide layer, improving corrosion resistance and durability.

Bead blasting achieves a uniform surface finish on aerospace components, removing contaminants and preparing them for coatings or treatments.

Powder coating provides a durable and corrosion-resistant finish to aerospace parts, enhancing aesthetics and protecting against environmental elements.

Electroplating deposits a metal coating onto aerospace components, improving conductivity, corrosion resistance, and surface appearance.

Polishing refines the surface of aerospace parts, enhancing their visual appeal and promoting smoothness for improved performance.

Brushing imparts a textured finish to aerospace parts, enhancing both aesthetics and functionality while providing a unique surface appearance.

Precision machining within the aerospace sector encompasses the exacting processes of cutting, shaping, and finishing components. This applies to crucial elements like aircraft engine parts, braking systems, and airframe components, guaranteeing superior manufacturing precision, optimal performance, and enhanced safety standards.

Createproto consistently delivers excellence. Their innovative solutions and attention to detail have elevated them to the forefront of aerospace part providers. Dependability, precision, and quality are second to none.

Eric Mitchell Aircraft Manufacturing Engineer

Createproto stands out for their exceptional aerospace parts. From tailored solutions to meeting the highest industry standards, their commitment to excellence is evident. For top-tier performance and reliability, Createproto is our preferred partner.

Gregory Davis Director of Aviation ServicesCreateproto serves a wide range of sectors such as medical, automotive, electronics, and aerospace, offering inclusive prototyping solutions that drive innovation and uphold standards of excellence

Createproto's aerospace parts are unmatched – precision engineering, cutting-edge technology, and a relentless commitment to quality make them our first choice for reliability and performance in critical aerospace applications.

Brian Thompson Airport Operations Manager