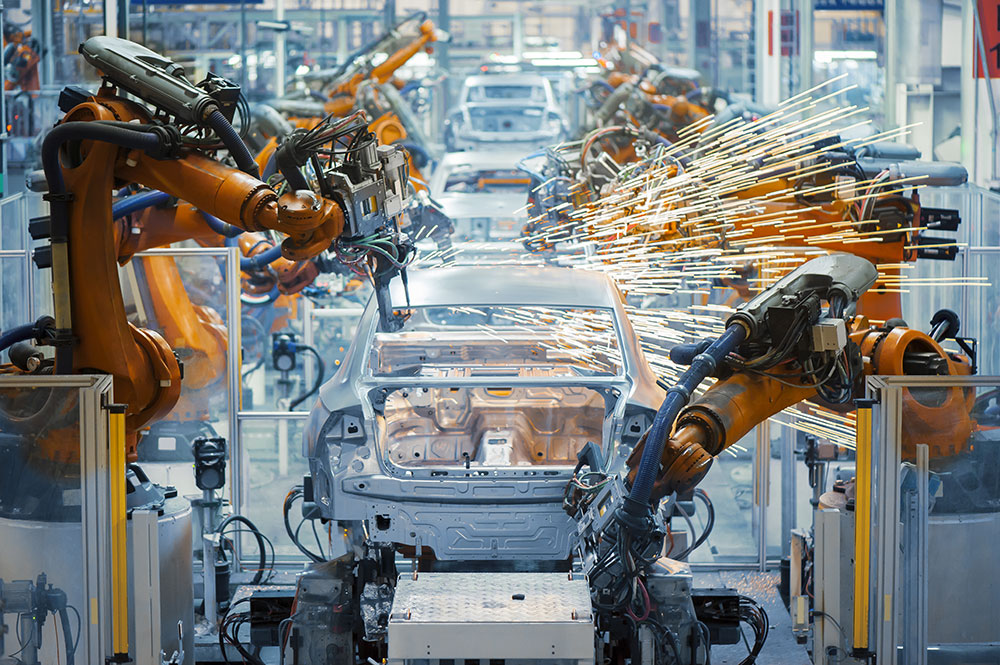

Explore the capabilities of our automotive CNC machining services for precision auto parts. CNC machining is primarily used for the custom processing of automotive engines, headlight lenses, suspension components, exhaust parts, and other automotive components.

Createproto leads automotive prototyping and production with expert engineering, cutting-edge technology, and a commitment to quality, ensuring accelerated development and production success

Createproto ensures automotive parts meet industry standards with precision and durability, employing advanced manufacturing techniques for high-quality, reliable components that withstand rigorous demands.

Streamlining the process, Createproto provides swift and accurate quotations, expediting decision-making in automotive part manufacturing, allowing clients to proceed promptly with confidence and efficiency.

Offering tailored solutions, Createproto accommodates diverse automotive needs. From materials to design intricacies, customization options empower clients to optimize parts for specific applications, enhancing overall product performance.

Createproto's agile approach and advanced technology enable instant problem-solving in automotive part manufacturing. Rapid response times and adaptive solutions ensure seamless progress, meeting the dynamic demands of the automotive industry.

Createproto’s automotive industry experts specialize in delivering precision cnc machine automotive parts, ensuring top-tier quality that meets industry standards. Leveraging advanced technology and a wealth of engineering knowledge, we provide tailored solutions, meeting the unique demands of automotive applications. From rapid prototyping to full-scale production, our commitment to excellence accelerates automotive innovation, helping manufacturers achieve their goals with efficiency and reliability.

Createproto’s automotive experts deliver precision with quality CNC machining, offering tailored solutions that accelerate innovation and ensure top-tier performance in parts manufacturing.

Explore the dynamic world of automotive prototyping, where precision meets innovation, shaping the future of high-performance and reliable parts

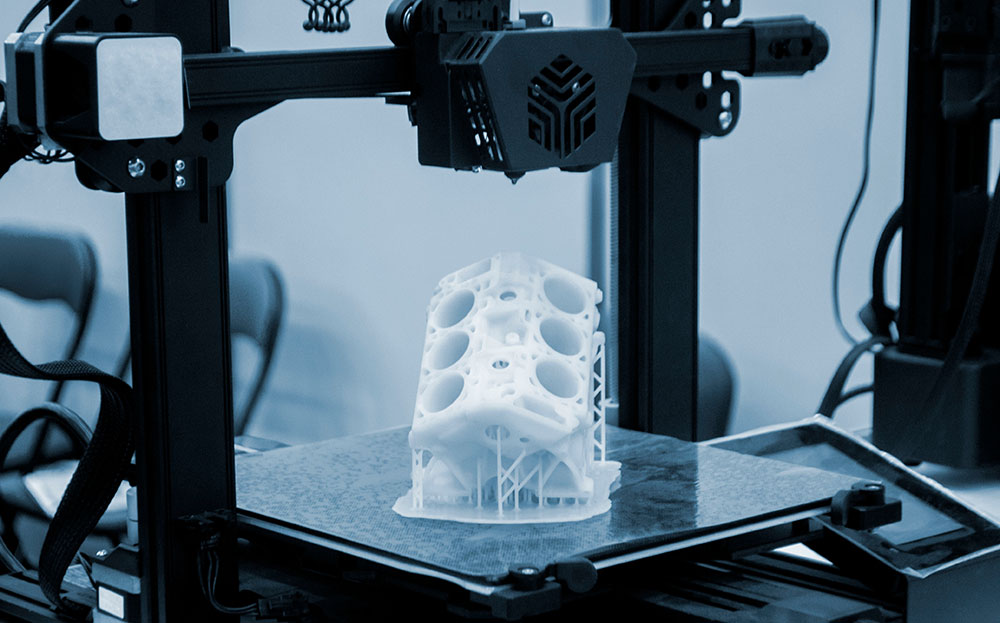

Automotive parts prototyping at Createproto involves meticulous design validation, leveraging cutting-edge technology for precision cnc machining and material testing. This iterative process ensures industry-standard quality, allowing for the development of high-performance and reliable components that meet the stringent demands of the automotive sector.

Explore Createproto’s design testing process, a meticulous phase ensuring automotive parts meet rigorous standards for precision, durability, and performance

At this stage, we will help you create prototypes according to your product’s requirements and design files. Depending on your needs, we will use low-cost materials and processes to develop parts similar to the final product. This allows you to examine the specification metrics and functional testing. Our advanced technologies also help us ensure the rapid turnaround of these prototypes.

Dive into Createproto’s Engineering Processing Testing, a meticulous phase ensuring automotive parts adhere to the highest engineering standards for optimal functionality

Createproto’s Engineering Processing Testing is a meticulous phase where automotive parts undergo rigorous examination for adherence to top-tier engineering standards. This comprehensive testing ensures optimal functionality and performance, identifying and addressing any potential issues to guarantee the highest quality and reliability in the final product.

Explore Createproto’s Production Testing, a crucial phase where automotive parts undergo rigorous examination to guarantee quality, reliability, and optimal performance in mass production

Createproto’s production testing is a pivotal phase, subjecting automotive parts to rigorous examination for quality assurance in mass production. Comprehensive testing ensures adherence to stringent standards, identifying and rectifying any issues, and guarantees that the final components meet the highest benchmarks for reliability, durability, and performance.

Embark on Createproto’s Final Production process, where meticulous precision and quality control converge to deliver impeccable automotive components meeting the highest industry standards.

Createproto’s Final Production process signifies the culmination of precision and quality control. Meticulous attention ensures each automotive component meets the highest industry standards. Comprehensive checks, adherence to stringent criteria, and iterative refinements guarantee impeccable, reliable, and durable products, meeting the demands of the automotive sector with excellence.

Createproto specializes in automotive body and frame expertise, leveraging advanced technologies and engineering prowess to deliver precision prototypes and production solutions, ensuring durability, performance, and industry compliance.

Createproto showcases expertise in automotive engine and powertrain prototyping, utilizing advanced technology to engineer components that ensure optimal performance, reliability, and compliance with industry standards.

Createproto excels in automotive suspension and steering systems prototyping, showcasing expertise in precision engineering and material selection to ensure components deliver superior performance, durability, and safety standards.

Createproto demonstrates expertise in automotive exhaust systems, employing advanced prototyping techniques to engineer components that optimize performance, meet emissions standards, and contribute to fuel efficiency and environmental compliance.

Createproto utilizes a diverse range of materials, including aluminum, steel, copper, magnesium, thermoplastics, and liquid silicone rubber, to craft high-quality and performance-driven automotive parts.

Aluminium, prized in the automotive industry for its lightweight composition and corrosion resistance, is extensively employed to enhance fuel efficiency and structural integrity in vehicle manufacturing

Steel, a robust and versatile alloy of iron and carbon, is a fundamental material in construction and manufacturing due to its strength, durability, and malleability

Copper, a ductile and malleable metal with excellent electrical conductivity, is widely used in various industries for its corrosion resistance and thermal properties.

Magnesium, a lightweight and highly reactive metal, is valued for its strength-to-weight ratio and is utilized in industries such as aerospace and automotive for lightweight structural applications

Thermoplastics, versatile and moldable polymers, become pliable when heated, allowing them to be shaped and reshaped, and find extensive applications in various industries for their flexibility and durability

Liquid Silicone Rubber (LSR), a versatile elastomer, boasts heat resistance, flexibility, and biocompatibility, making it a preferred material for diverse applications, including automotive, medical, and electronics industries.

Electrochemical process that enhances metal surfaces, providing corrosion resistance and vibrant color finishes through the formation of an oxide layer.

Precision surface treatment using fine abrasive beads to achieve a smooth, uniform finish on metals, plastics, or ceramics.

Durable and vibrant finish for surfaces, achieved by applying electrostatically charged powder particles that adhere and fuse upon curing, enhancing both appearance and protection.

Electrochemical process that deposits a thin, protective metal coating onto a substrate, enhancing aesthetics and providing corrosion resistance.

Chemical treatment that enhances corrosion resistance by forming a protective oxide layer on the surface of metals, particularly stainless steel.

Controlled application of heat and cooling processes to alter the physical and mechanical properties of materials, enhancing their strength, hardness, and durability.

Machining metal in the automotive industry involves precision cutting, shaping, and finishing of components. Applications include engine parts, brake components, and chassis, ensuring high-quality manufacturing, performance, and safety.

Machining excellence—our brakes, gears, and chassis components boast unmatched durability, ensuring safety and superior automotive performance

Marcus Turner Auto Dealership Sales Manager

Reliable machining transformed our transmission systems. Smooth shifts, enhanced durability—testimonial to precision engineering, a game-changer in automotive innovation

Ryan Mitchell Automotive TechnicianCreateproto caters to diverse industries, including medical, automotive, electronics, and aerospace, providing comprehensive prototyping solutions for innovation and excellence

Precision machining elevated our engine performance, delivering power and efficiency. Exceptional quality for automotive excellence

Jason Reynolds Automotive Service Manager