At CreateProto, we are offering custom rapid prototyping and manufacturing services for 3D printing for industrial needs. With us, you can get rapid iteration and a new version of parts within a week.

Our rapid prototyping and manufacturing services for 3D printing are the best way to produce functional industrial-grade parts for the automotive, aerospace, and medical sectors at a lower cost to meet on-demand production.

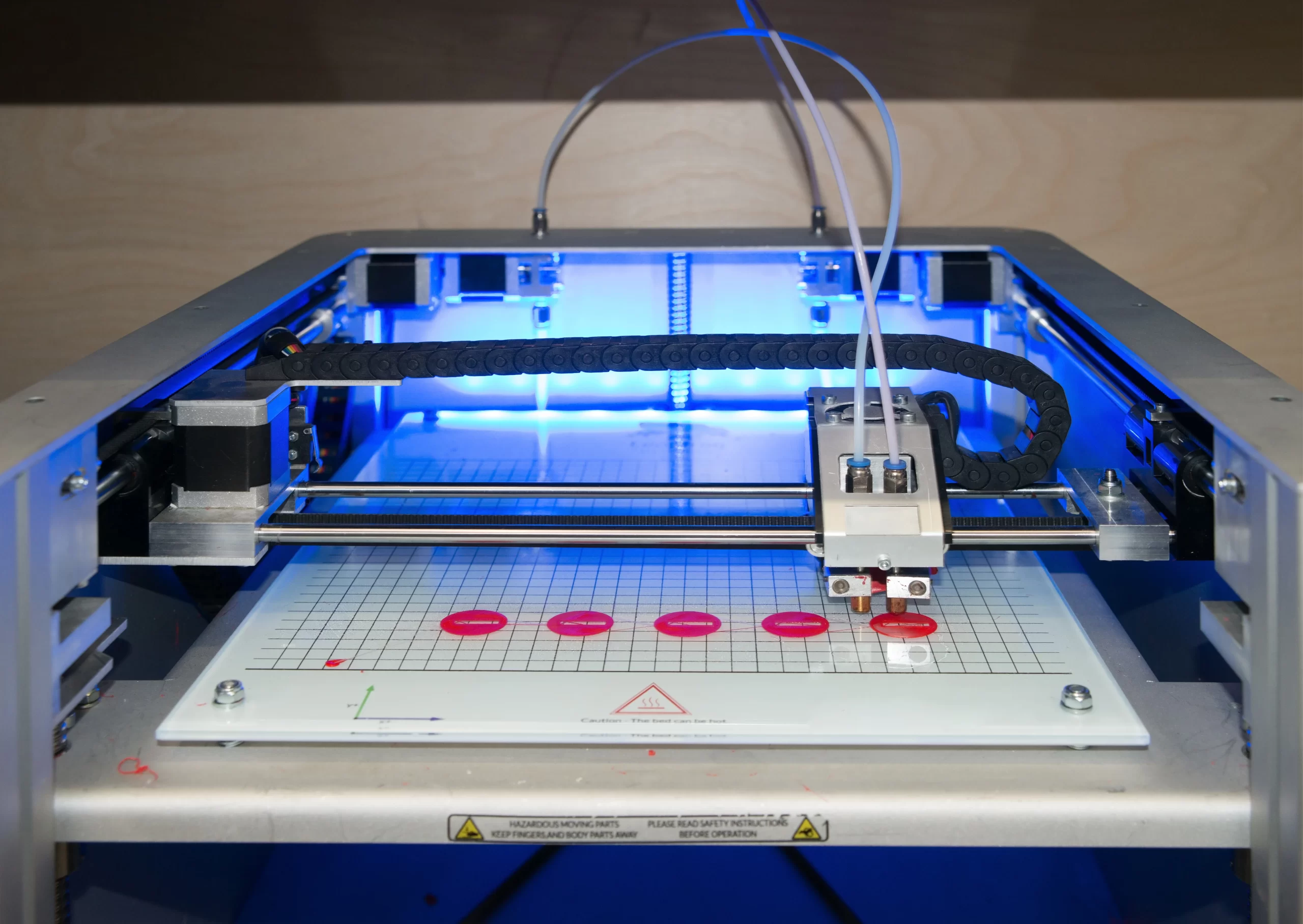

Stereolithography comes with unparalleled precision through the photopolymerization process using a laser to transform liquid resin into hardened plastic. We ensure high accuracy and smooth surface features using advanced materials, ideal for high-detailed prototypes.

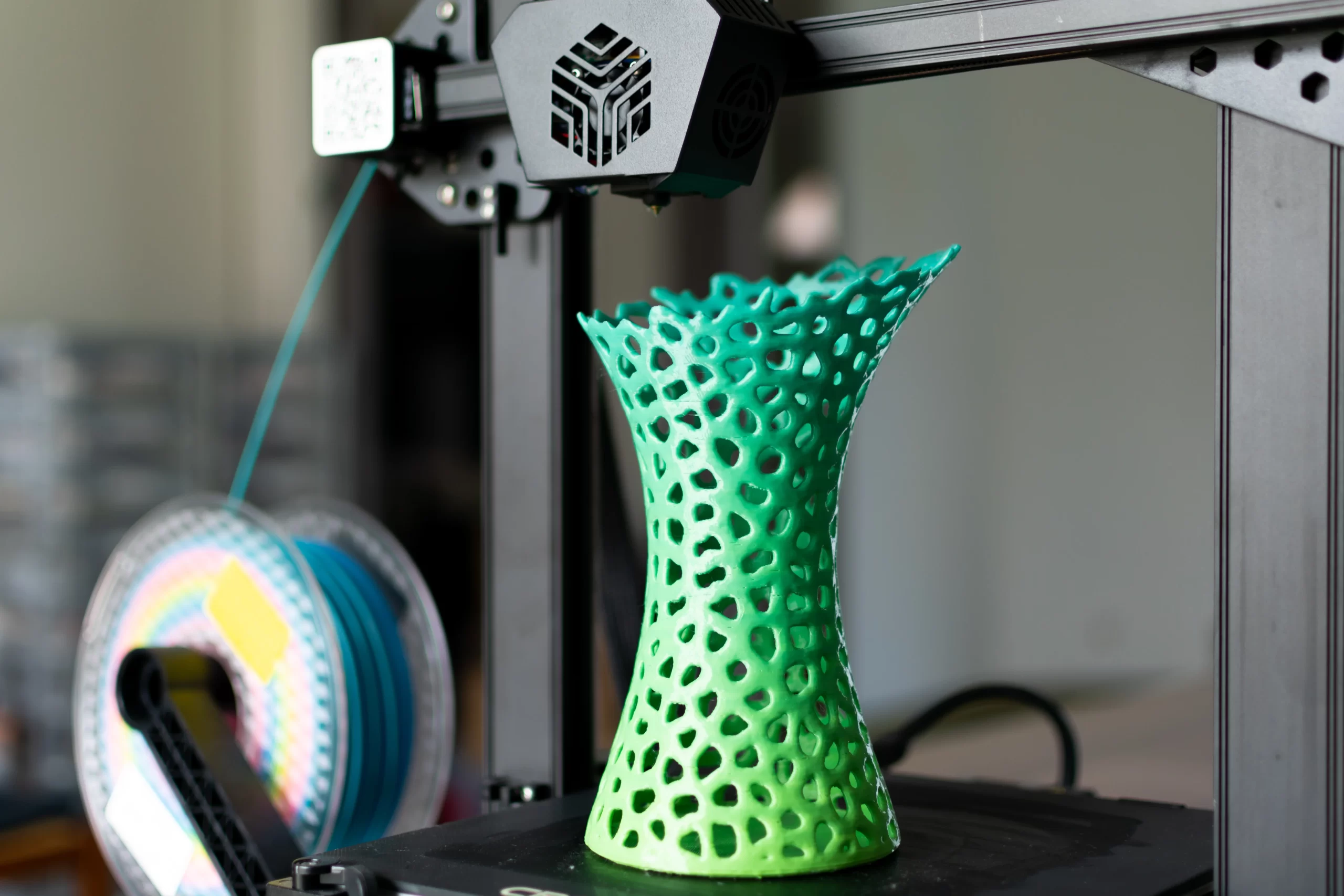

Fused Deposition Modeling is the most commonly used service for basic proof-of-concept 3D models layer by layer melting the materials with a heated nozzle. Our experts ensure precision and top-notch quality.

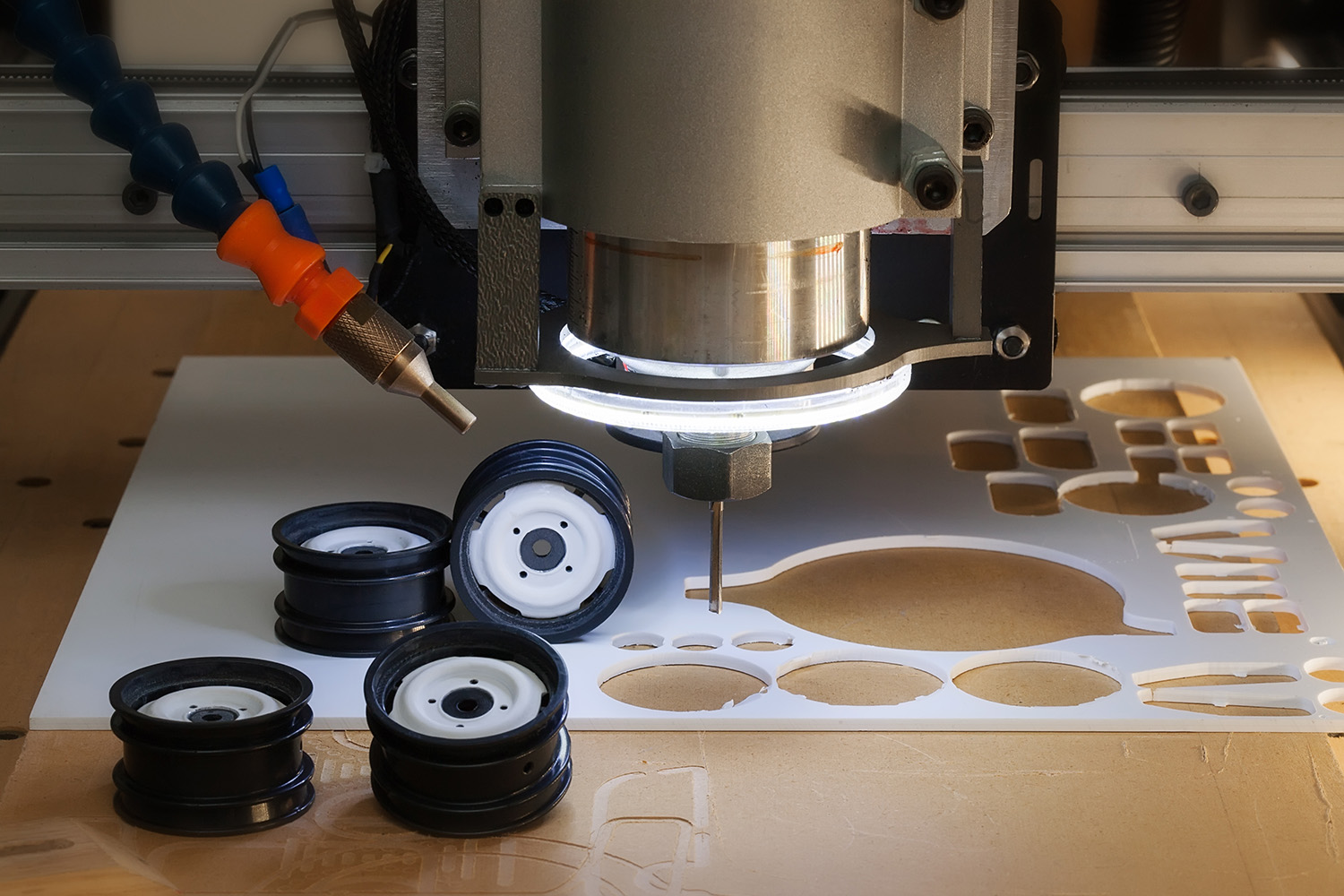

Selective laser sintering offers impressive accuracy and quick turnaround for end-use parts, functional prototyping, and custom short-run manufacturing. We guarantee the best outcomes for interior features and complex geometries.

At CreateProto, we are offering custom 3D printing prototype services online where you can get a quick customized quote within 7 hours or less from our Quick Quote tool for your machined parts.

As soon as you apply for a quote, our experts get back to you with an estimated price and DFM feedback. From sending a file to the printer to offering a new version- We ensure fast turnarounds within a week.

Our 3D printing manufacturers provide rapid iteration for the parts you want to get designed with utmost design flexibility, which means you can make changes in the products for further development and production.

The 3D printing process is ideal for the automotive, medical, and aerospace industries to create parts for on-demand production. We guarantee on-time delivery with precision and design flexibility, even for complex geometries.

Get high-quality 3D prints tailored to your project’s unique requirements, ranging from individual prototypes to large-scale production runs, all delivered within a matter of days. Our commitment is to meet your demands for both quality and quantity.

Opt for 3D-printed injection molds to enhance the iterative process, facilitating swift design revisions and prototyping. This pioneering approach not only minimizes costs and time but also provides a more efficient pathway from conceptualizing designs to final creation.

Rapidly produce new iterations and multiple fully-functional prototypes through 3D printing. This solution adeptly addresses challenges in prototype development by minimizing time spent and enhancing design adaptability, resulting in a more seamless project execution.

Leveraging advanced 3D printers with the capacity to handle larger batch sizes and a variety of materials beyond polymers, we efficiently address challenges related to inventory management and enhance production scalability.Our solution enables clients to 3D print orders on-demand.

At CreateProto, we strive to meet accuracy and top-quality for 3D printed prototypes. Leveraging our advanced tools and testing, our experts offer tight tolerance and impeccable quality for each part we design.

| Name | Description | Materials | Color | Texture | |

|---|---|---|---|---|---|

| Polishing | It’s the best way to give your 3D-printed parts and prototypes a smooth and glossy finish by rubbing it physically or chemical interference, especially on materials, such as steel, stainless steel, aluminum, and brass. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. |

| Painting | If you want to improve the aesthetic appearance, painting the surface is an ideal option. Also, it will create a protective effect on them and give a gloss, semi-gloss, metallic, or flat texture as you need. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Matte |

| Powder Coating | We apply dry and free-flowing powder in the case of powder coating the 3D printed parts and prototypes, apply it electrostatically, and cure it under ultraviolet light or heat to give a gloss or semi-gloss finish as per your needs. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Bead Blasting | With bead blasting, you will get a smooth surface with a matte textured finish on 3D-printed parts. It’s usually used on ABS, steel, aluminum, and brass material parts for visual applications and surface treatments. | Aluminum, steel, stainless steel | N/A | Smooth, glossy finish |

We use advanced materials to offer fine features and smooth surface finishes to 3D printing rapid prototyping parts and prototypes so you get the desired aesthetics, functionality, and mechanical properties. Choose the right one for your parts.

PLA is a biodegradable thermoplastic with high stiffness, good physical properties and detailing, and affordability. For its small stripe effects and 0.2 mm accuracy, it’s ideal to use for 3D printed parts.

ABS is a great choice for 3D-printed prototyping due to its thermal and mechanical properties. This thermoplastic comes with fewer defined details and great impact strength.

With great strength, toughness, and impact resistance, Nylon is a perfect material to create 3D printing parts. This thermoplastic has good heat resistance and mechanical properties with a powder finish.

Do you want to improve the aesthetics, durability, and functionality of your 3D-printed prototypes and parts? A smooth surface finish is necessary. Here are the choices, we, CreateProto, bring for you.

| Name | Description | Materials | Color | Texture | |

|---|---|---|---|---|---|

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. |

| Bead Blasting | Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Matte |

| Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, stainless steel | N/A | Smooth, glossy finish |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Satin |

For every 3D printed prototype and part manufacturing, we strive to meet industrial-grade quality each time. Our experts ensure providing rapid iteration and on-demand production within a week without compromising quality.

Just upload your CAD files and apply for a quotation from our Quick Quote tool. And, our experts will get back to you within 7 hours or less with an estimated cost and DFM feedback.

Although lead times depend on the design complexity, its size, and the 3D printing process you choose. Our lead time is as quick as 7 days, even within 2 to 3 business days in some cases.

We offer a wide range of surface finishing options and material choices for 3D-printed parts. Also, we have an efficient in-house 3D printing team of professionals to handle any small or big on-demand production.

It’s been two times we have worked with CreateProto, and honestly, they have never disappointed us. We just requested the quote, and they have handled the rest, from product design to production to testing and launch- All the fulfillment required for our projects so far. Professionalism and convenience- Perfect reasons to work with them!

Avram Mckinney Mechanical Engineer Associate, Thermaco

It’s really impressive working with CreateProto for our automotive projects. Quick responses all the time that has eased communication. We don’t have to manage or juggle suppliers. They got us all covered! In fact, their prices are too competitive, even for mass customization and low-volume production.

Timothy Frederick CAE Mechanical Engineer, BirdSed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo.

3D printing or additive manufacturing processes produce three-dimensional objects through material depositing layer by layer on a digital design. It brings a digital model into life using metal, plastic, or resin.

3D printing is an ideal choice for various industrial needs, from automotive to medical to aerospace sectors. In the key applications, there are prototyping, medical implants, metal casting patterns, lightweight parts, and much more. We also offer custom 3D printing services as well.

3D printers we use at CreateProto strive to achieve 25 to 50 microns to offer exceptional smoothness and finish. You can expect a unique texture and detail from our 3D printed prototypes.

3D printing is an additive manufacturing process, whereas CNC machining is a subtractive method. The first one deposits materials layer by layer and the latter removes the sections of a solid material block to achieve the desired part.

Our 3D printing process can achieve excellent accuracy where the standard tolerance remains ± 0.1mm for 3D printed parts. However, it depends on the design complexity that we evaluated once you upload the CAD file.

Usually, our lead time for 3D-printed prototypes and part manufacturing is within 7 business days. But, it can vary based on part height, size, complexity, and the 3D printing process you choose.

The size of your 3D-printed parts and prototypes depends on the specifications you select. We have different 3D printer types to print part models in different sizes, like SLA comes with up to 29" x25" x21", while SLS with 26" x15" x23".

We recommend the file formats for 3D printing are solid 3D CAD files, STEP (.stp), and STL (.stl).

Our price for 3D printing prototyping starts at nearly $95, which can change based on size, printer choice, design complexity, part volume, and material uses. However, you can apply for a quote by submitting your design in 3D CAD models.

Whenever and whatever we have needed, Createproto has delivered every time with the exact precision and quality required. Faster turnarounds, perfect finish, and on-time delivery for product launch- Great experience working with them. We appreciate their professionalism and are looking forward to teaming up with them again.

Tyler Richards Lead Mechanical Engineer, Shimano