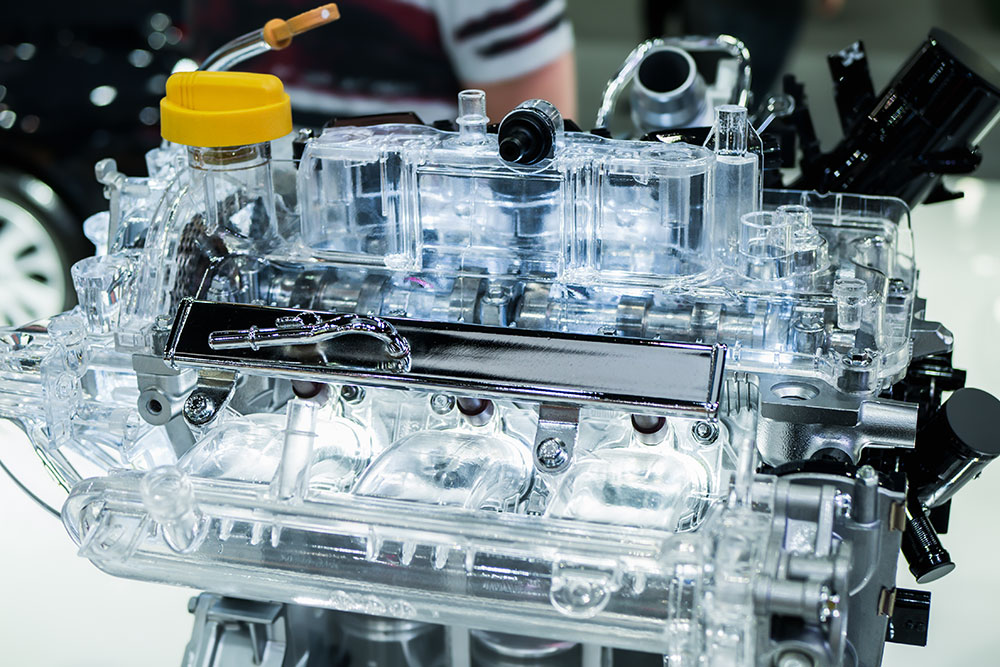

CreateProto leverages clear prototyping services with offering high-quality, custom-made prototypes. We use various techniques including CNC machining, cnc milling Acrylic(PMMA), PP, PC or ABS, surface polishing and vapor polishing to create clear prototypes that meet the exact specifications of our clients.

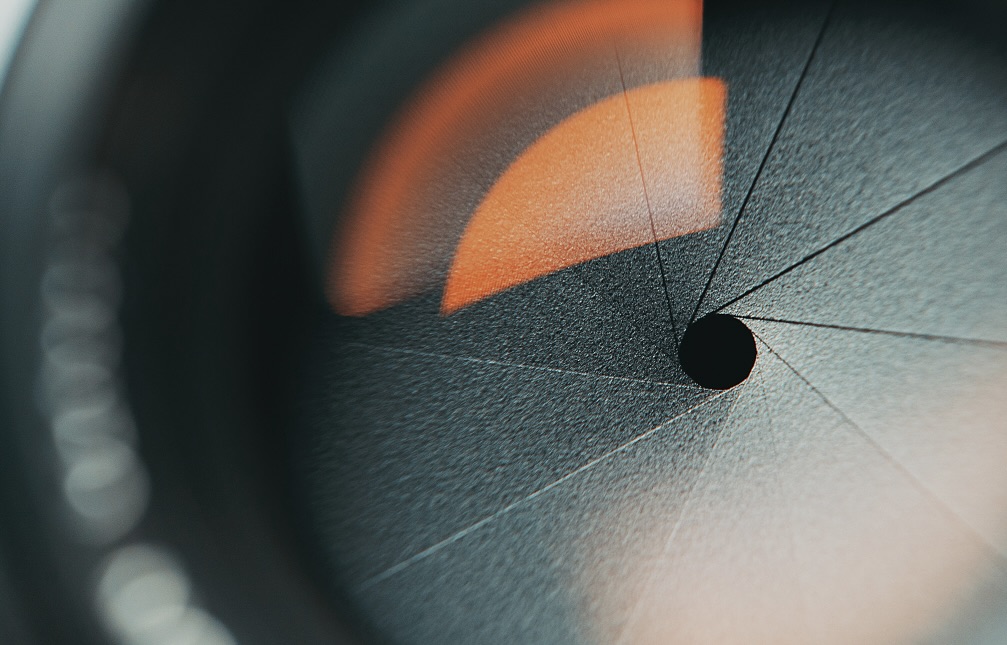

We offer a precise and versatile manufacturing process that produces top-quality parts with a mirror-like surface finish. Used in top-notch industries like medical, aerospace, and customer electronics, we offer exceptional services.

Experience excellent optical clarity with versatile thermoplastic with well-implemented precision machining and finishing processes. It is effective to produce huge products from medical devices to automotive components.

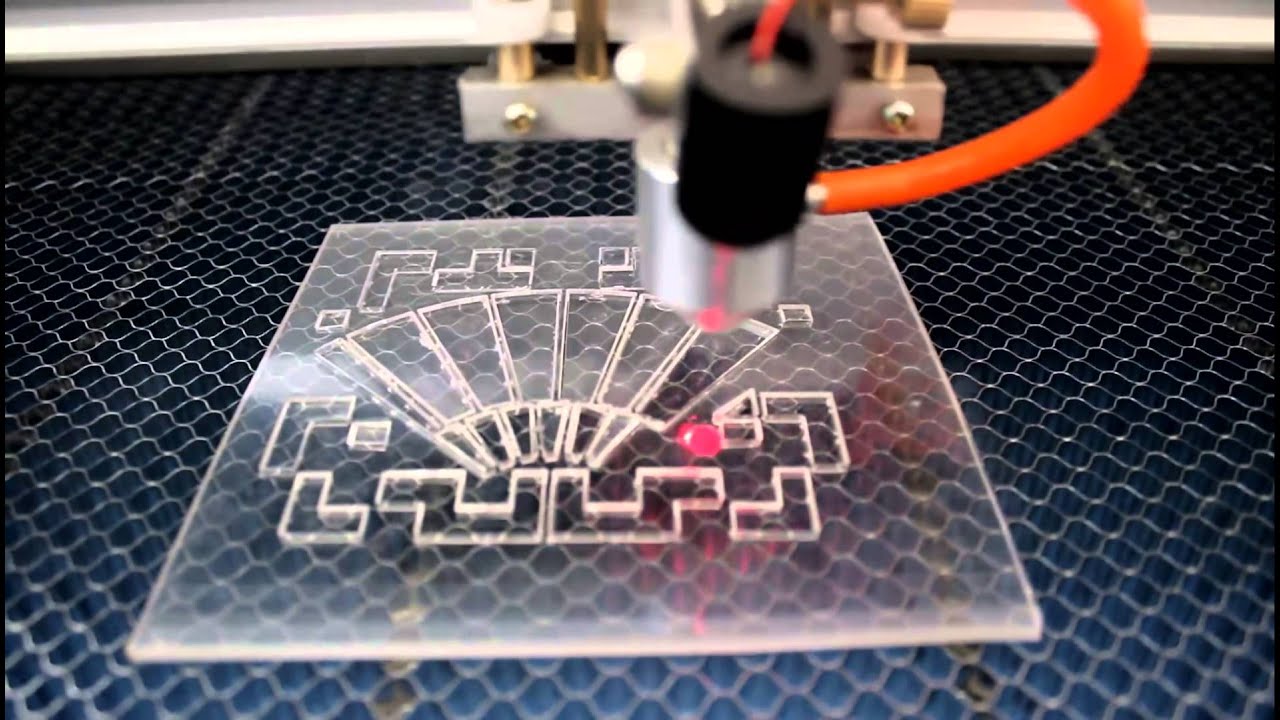

Our rapid prototyping process uses computer-aided tools to generate high-quality, transparent prototypes from acrylic sheets. Known for its affordability, speed, and precision, it is a popular choice for top industries.

Harness the power CreateProto and the best clear prototyping services. With our state-of-the-art technology, skillful team, and commitment to quality, we strive to offer the finest services in the industry. Get fast, affordable, and accurate prototypes with us.

CreteProto’s clear prototyping services offer perfect-finish prototypes that are crystal-clear, that is, fully transparent.

Our prototyping services are absolutely accurate and precise, ensuring :that your preferred design is transferred to the production process with the highest precision.

We also offer affordable services so that it is accessible to businesses of all sizes. This makes it easy to get high-quality prototypes without breaking the bank.

CreateProto offers a wide range of clear prototyping services to meet your needs. Whether you need a prototype for functional testing, aesthetic evaluation, or marketing purposes, we can help.

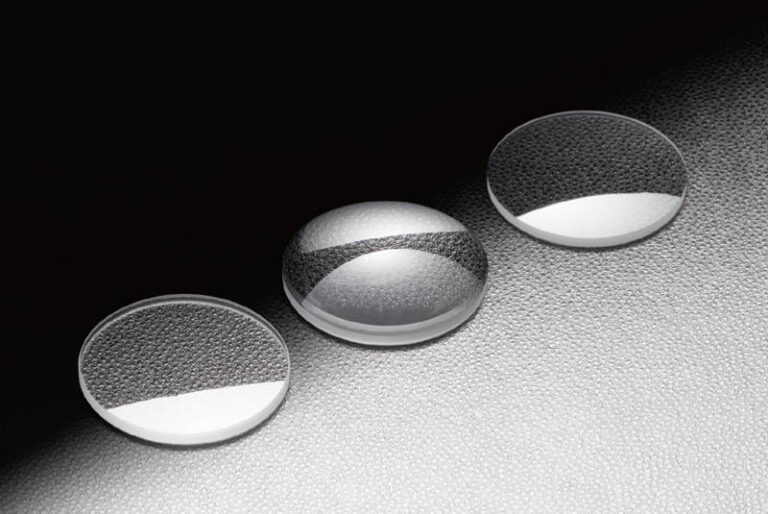

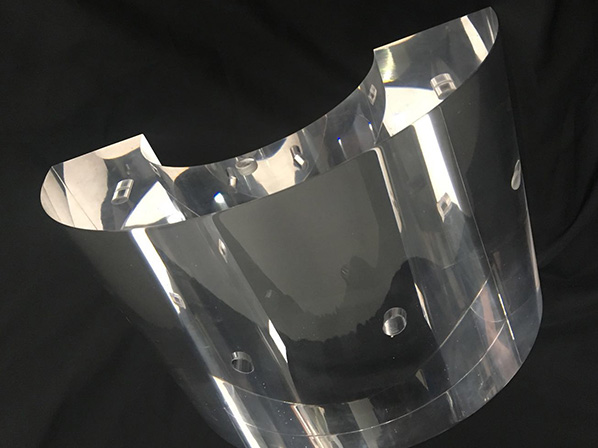

Clear plastic parts are utilized in many prototyping applications to achieve optical functions, view the inside of products, or enhance aesthetics. Createproto provides a range of solutions for custom clear parts and optical components, including CNC machining, cnc milling service, injection molding, and vacuum casting. We have top-notch expertise and polishing techniques to achieve optical clarity on plastic parts, and we fully support optical prototype development projects for all business types.

Witness high-quality clear prototypes manufactured using the latest technology and a variety of prototyping techniques. It is available in a vast range of materials, including acrylic, polycarbonate, and urethane.

Master pattern: Clear casting needs high transparency that is required to be acquired by the use of acrylic material by CNC machining. Standing seamless with 1500# sanding paper, the polishing paste is used to remove the sanding mark.

Silicone rubber mold: The silicone mold material is to be compatible with clear casting resin. Also, finding the right release agent and applying it effectively is essential.

Mold life: For clear casting 12-15 copies efficiently, up to 20 copies per mold.

Accuracy of cast parts: It offers a standard tolerance of +/-0.15 mm/ 100mm, the highest precision can be +/-0.05 mm.

Minimum wall thickness: It is essential to have a minimum wall thickness of about 0.75 mm. According to the recommendation, 105mm would suit the best.

Maximum part dimensions: The entire size of the mold is limited to a size of 1200*600*600mm for clear casting and the maximum volume is assumed to be 4 liters.

Finishing cast parts: Polishing the finishing parts comes at the epitome. The parts require the removal of parting lines and sprues that give the finest touch to the finished products.

Urethane vacuum casting is the ideal solution for creating small quantities of optically clear plastic prototypes quickly and affordably. CreateProto has extensive experience in this field and can produce parts with impeccable surface finish and the highest optical pattern details.

Rapid injection molding for clear plastic is a revolutionary process that allows you to test low-volume production runs using the same materials and technology that will be used for final production. CreateProto is a leading provider of rapid injection molding services for clear plastic parts. Our team of experienced technicians can help you with all aspects of the rapid injection molding process, from design to production. We also offer a wide range of post-processing services, such as polishing and electroplating, to give your clear plastic parts the perfect finish.

Urethane resin is a versatile prototyping material that is known for its clarity, durability, and affordability. It can be used to create a wide range of prototypes, from simple to complex, and is available in a variety of colors and finishes.

Axson PX-5210 is a clear urethane casting system used for prototyping and production of transparent parts. It offers excellent clarity, dimensional accuracy, and surface finish.

PX-527 is easy to process and can be cast in a variety of molds, including silicone, urethane, and metal. It is also compatible with a wide range of pigments and colorants, making it possible to create custom-colored prototypes.

Our ISO 9001:2015 certification and manufacturing excellence make us your trusted partner for advanced service, quality, and compliance.

Get the finest precision machining at your fingertips. Upload your design to our ever-learning instant quotation platform and receive the best pricing and lead time in minutes. (if parts do not meet standards, 100% rework or refund).

We use the latest technologies and materials to produce clear prototypes with excellent clarity, dimensional accuracy, and surface finish.

We have a team of experienced engineers and technicians who are experts in clear prototyping. We can help you choose the right material and process for your project, and ensure that your prototypes meet your exact specifications.

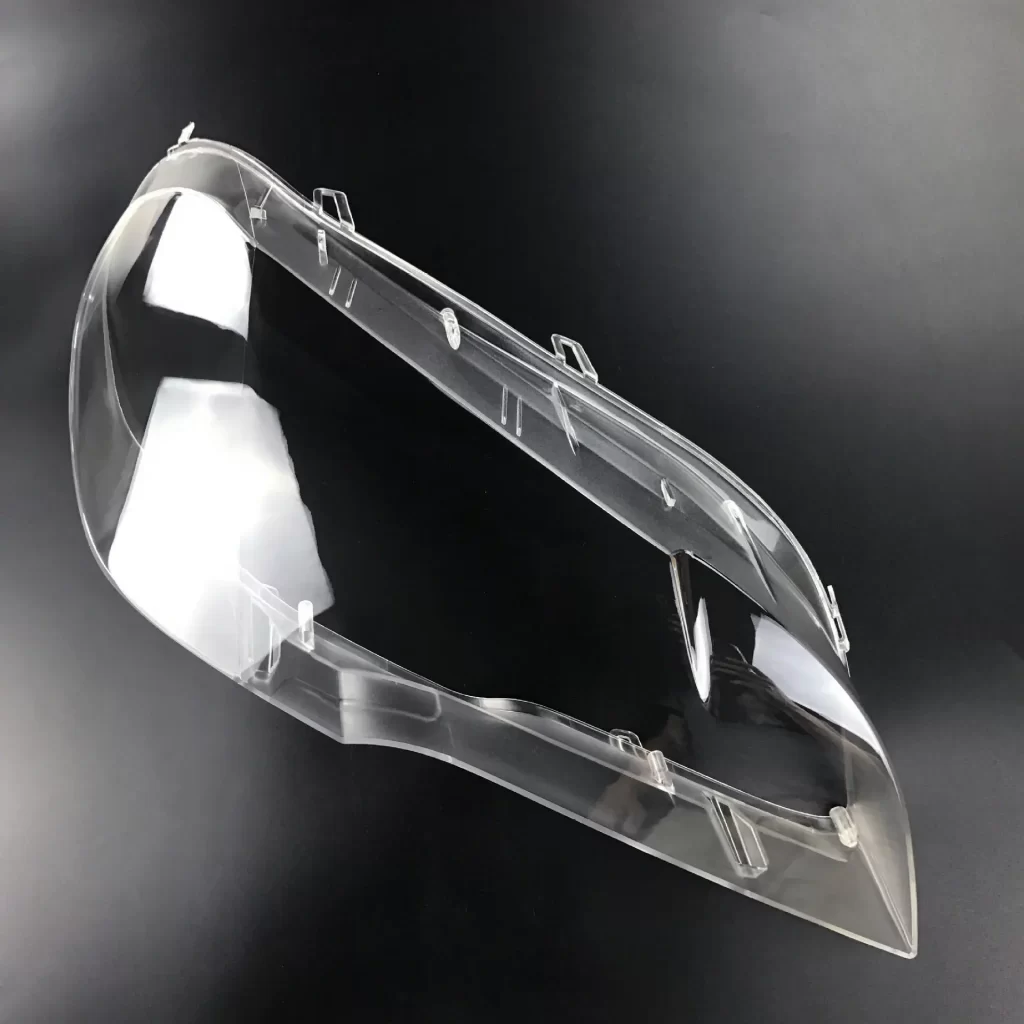

Clear optical prototypes are used to simulate the performance and appearance of final production cnc milling parts in a variety of applications, including automotive lighting, aerospace, medical, consumer electronics, and a lot more.

Polycarbonate and Acrylic are the two prime and popular choices for clear optical prototypes for their exceptional clarity, durability, and versatility.

CNC machining is definitely better than injection molding for prototypes as it is faster and more flexible. Depending on the complexity you can have a prototype in a matter of days or even hours.

Prototypes help the automotive industry and their engineers to test and refine their designs before they are mass-produced. This helps to ensure that the vehicles are safe, reliable, and efficient.

It can. Depending on the materials used in the clear prototyping process, the prototypes produced by Createproto can withstand harsh conditions too.

Look no further than Createproto. Our highly trained and experienced team is dedicated to offering exceptional clear prototyping service in the industry. Give us a call to know more!