We, CreateProto, are offering custom CNC machining services, from functional prototyping to on-demand production for low-volume parts, fixtures, Get instant pricing for CNC machined metal or plastic parts from over 50 certified materials. We source high-quality raw materials to ensure each component is durable and reliable.

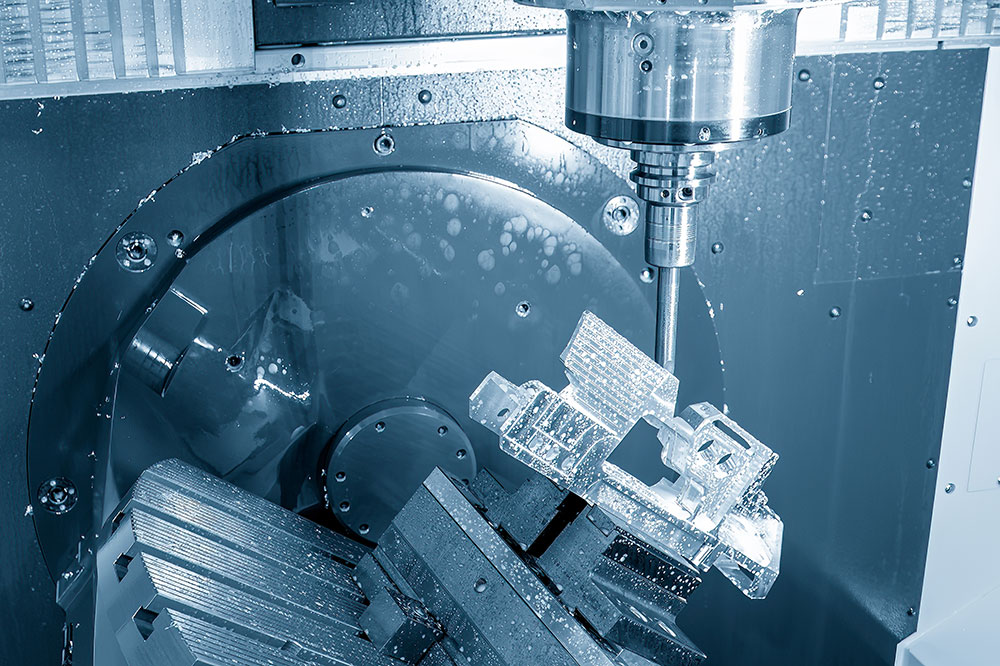

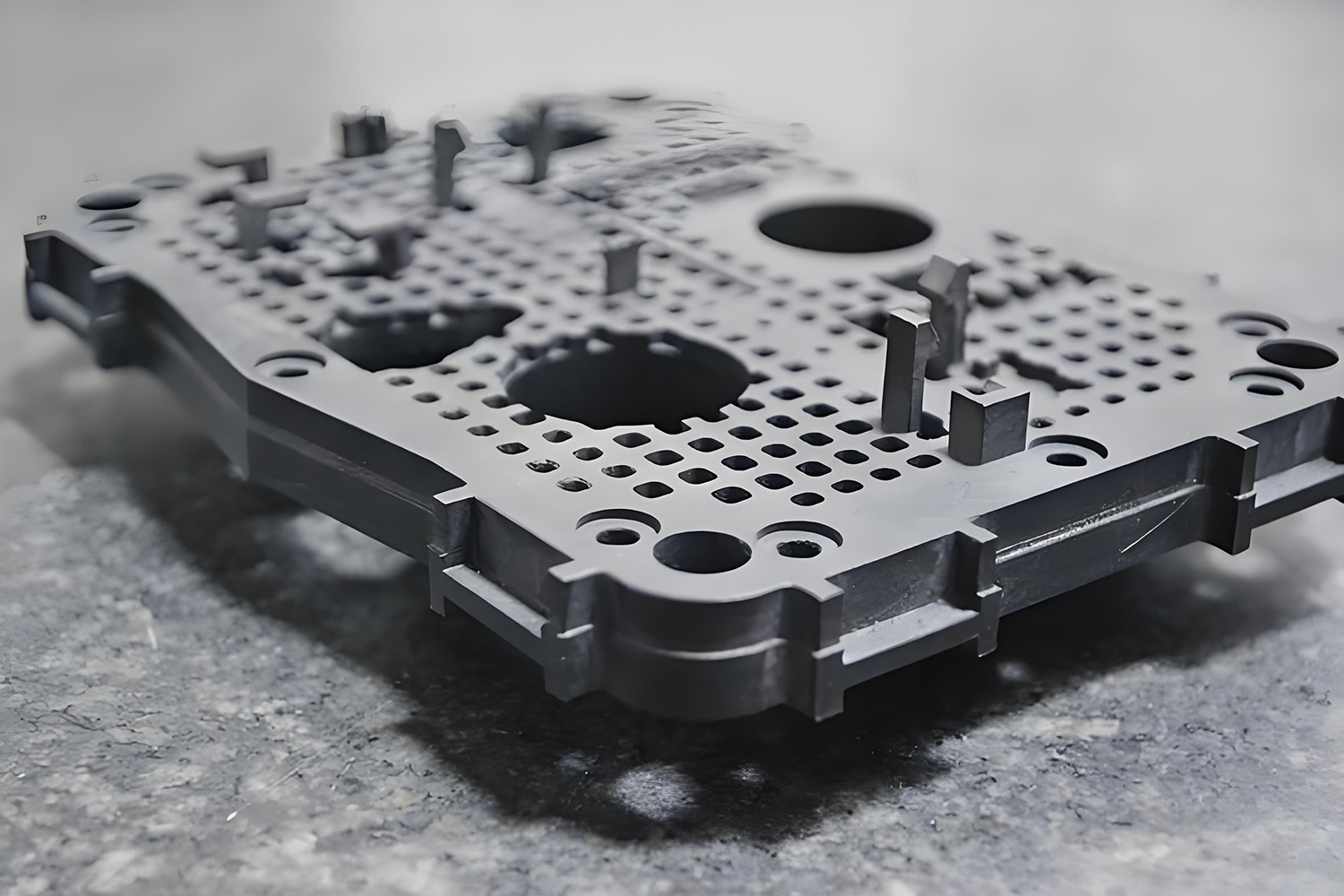

Whether it be functional prototypes or low-volume production, our custom CNC prototype machining has got all you covered. At CreateProto, we offer a wide variety of services, from CNC milling to turning to 3-Axis, 4-Axis & 5-Axis CNC Machining, CNC Swiss Machining & EDM.

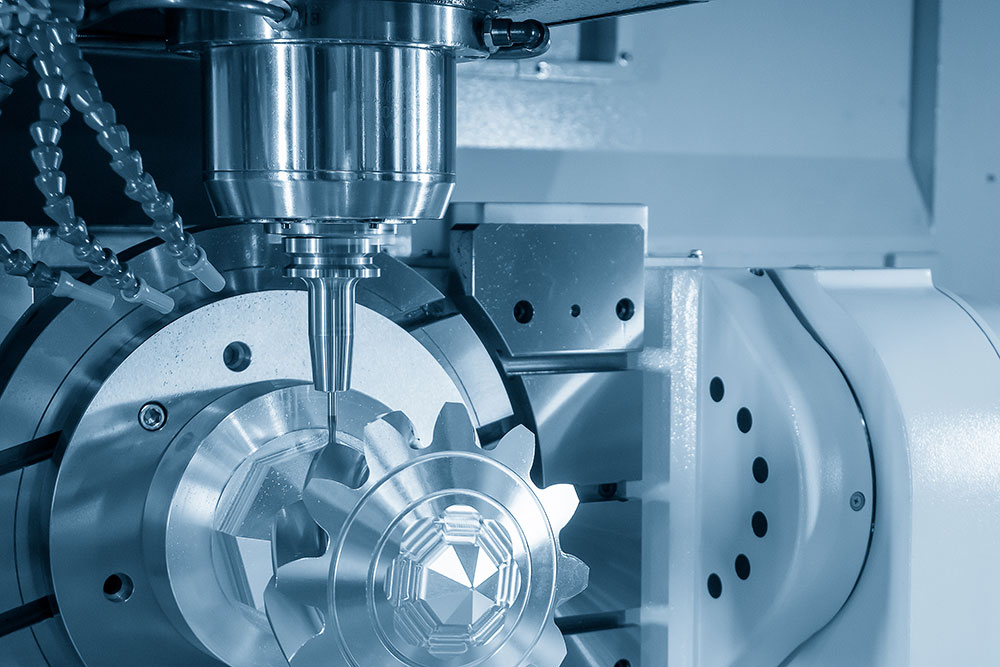

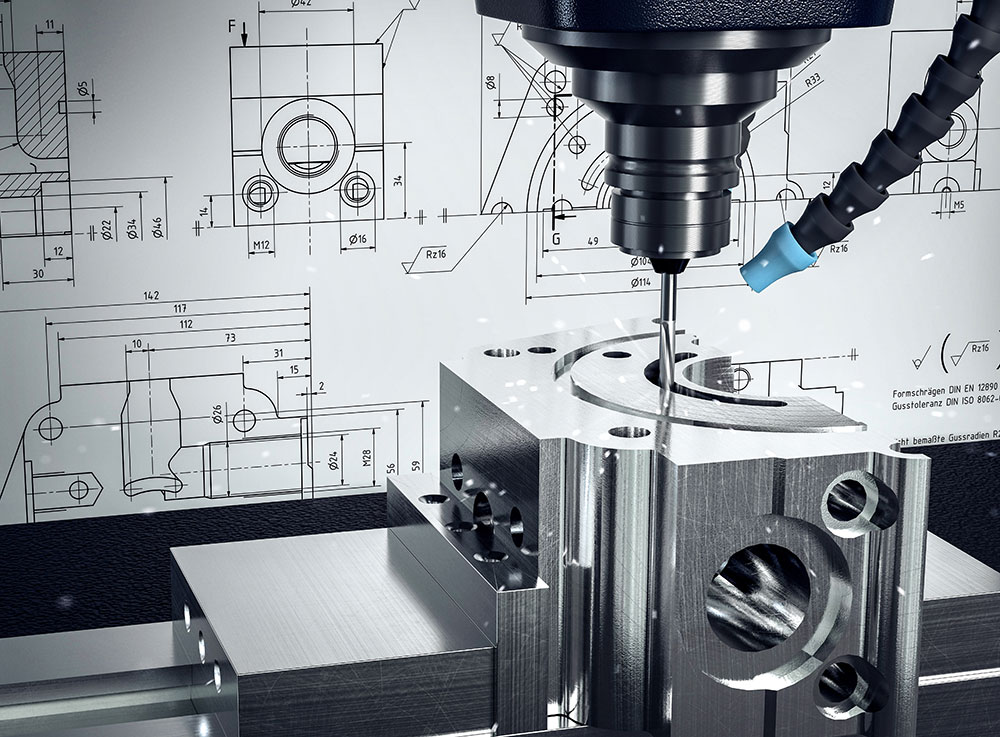

In the CNC milling process, we use a milling machine, including multi-point cutting tools to remove materials from the initial metal block and give different shapes and lengths sharply.

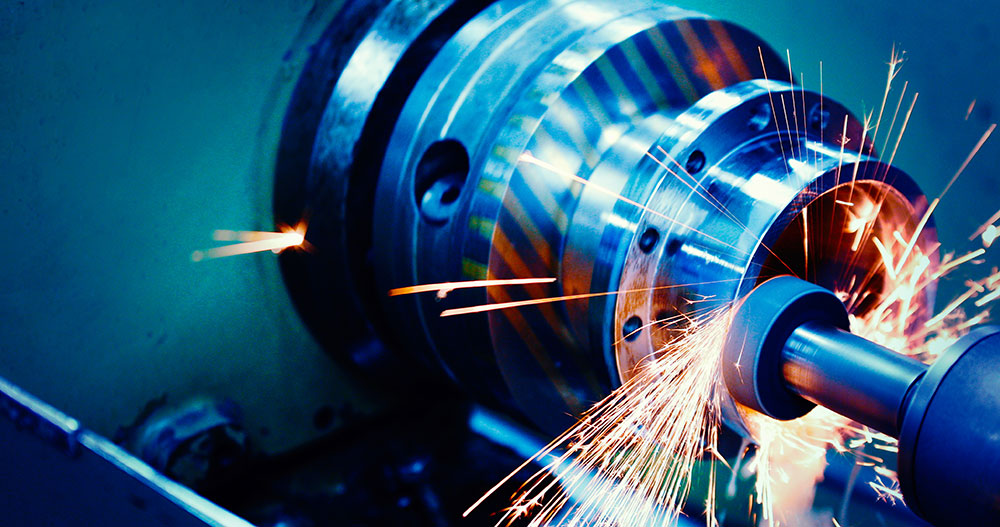

For detailed prototyping, our experts use a lathe tool, consisting of a single-point cutting tool to create cylindrical parts to give linear features on the prototype edges while slots and threads on the interior.

For complex geometries for CNC prototypes and part production, we leverage multi-axis CNC machines, including 4-axis, 5-axis and Swiss CNC machining to ensure providing the highest tolerances.

As the leading custom CNC machining manufacturer, we strive to provide a quick customized quote just within 3 hours or less with detailed DFM feedback. Get a quote from our Quick Quote tool.

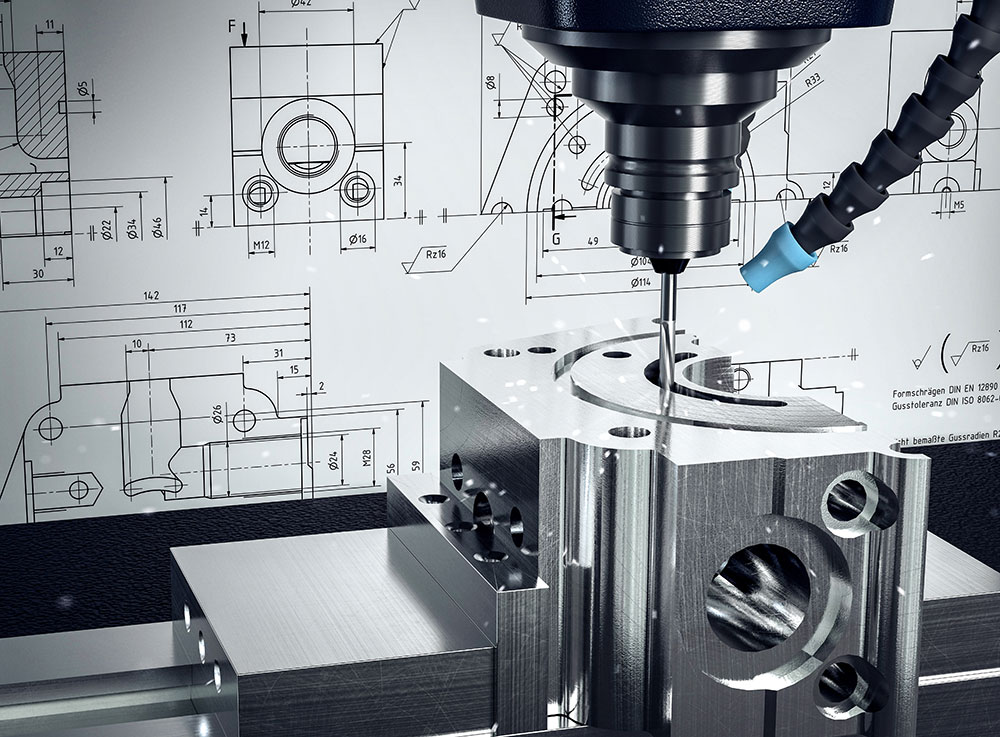

When you apply to get a customized quote and upload your CAD file, we evaluate your product design first and get back to you with the best possible DFM feedback within a few hours.

Upload your product design and click for a customized quotation, we will be right back to you with a real-time estimated pricing after evaluating it just within 3 hours or less.

From quotes to orders to completion- We take care of the entire CNC prototype projects step-by-step. Our experts oversee each stage of every project carefully to ensure transparency and ease of access.

CNC machining is a computerized manufacturing procedure used for low-volume production and rapid prototyping. Here’s how we work step-by-step, from prototyping to production.

We start our process with rapid prototyping to deliver designed parts in the short lead times, while fixing design errors faster, saving on time and costs, and making it market-ready.

Between the part design and the original products, there are gaps to fill out. Don’t worry! We have professional engineers to recommend the best practical design for your machined parts.

We guarantee to offer on-demand supply for CNC machining metal and low-volume production with high standards and accuracy for every product while balancing efficiency, quality, and costs and guaranteeing precision.

At CreateProto, we maintain the highest standard for metal CNC machining services with ISO 9001:2015 accreditation. If you want custom standards and tolerances, specify them on your product design model.

| Standards | CNC Milling | CNC Turning |

|---|---|---|

| Maximum Part Size | 4000×1500×600 mm 157.5×59.1×23.6 in. | 200×500 mm 7.9×19.7 in. |

| Minimum Part Size | 4×4 mm 0.1×0.1 in. | 2×2 mm 0.079×0.079 in. |

| Standard Tolerances | Metals: ISO 2768-f Plastics: ISO 2768-m | Metals: ISO 2768-f Plastics: ISO 2768-m |

| Lead Time | 5 business days | 5 business days |

| Text | Minimum depth is 0.1 mm and width 0.5 mm are created using laser carving or CNC engraving to bring standard texts if required | Minimum depth is 0.1 mm and width 0.5 mm is followed to create standard text using laser marking for CNC turned parts |

| Threads And Tapped Holes | Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter | Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter |

We are offering a wide array of options for edge condition at CreateProto, as per client requirements be it cnc machining auto parts or metal fabrication service for medical devices or any other cnc mchining parts. Our services include edge trimming, deburring, edge rolling, edge conditioning, and edge beveling, to eliminate sharp edges and enhance aesthetic appeal.

With us, you can get a variety of material options for rapid prototyping of custom complicated parts. According to your manufacturing needs, budget, and required lead time, you can choose from these machining materials.

Due to being a highly ductile metal and having a great strength-to-weight ratio, it’s easy to machine for different applications.

Steel is a popular choice for industrial applications for its hardenability, durability, and corrosion resistance. It’s an alloy of iron and carbon.

Due to offering a number of properties, stainless steel is the most sought-after material for industrial applications.

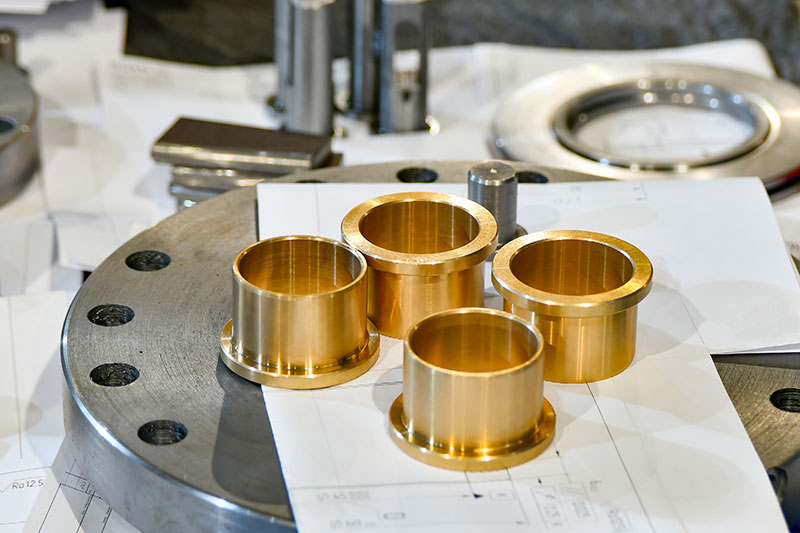

It’s another popular choice for different industrial applications for its ductility, strength, and machinability as bronze consists of tin, copper, and other metals.

Brass has all the desirable properties required for industrial applications, from electrical conductivity to low friction and golden appearance.

It’s the best material choice for CNC prototypes and low-volume part productions for its electrical and thermal conductivity, corrosion resistance, and plasticity.

CNC machining enables precise fabrication of various plastic materials, providing the manufacturing industry with more efficient and reliable production methods, whether for simple components or intricate assemblies. These include ABS, PP, PE, PVC, PS, PC, PU, Nylon, POM, PMMA, PTFE, and EP…

CNC machining can cause visible tool marks on the machined parts due to eliminating areas from the metal block’s surface to give it the desired shape. To improve aesthetics, you can give it a different surface finish. Select from here.

The bead blasting process gives CNC machined parts a matter texture and smooth surface, ideal for visual applications for aluminum, stainless steel, brass, and ABS. Also, for other surface treatments, this process is commonly used.

It’s another popular surface finish used for steel, stainless steel, and aluminum CNC machined milling parts as a dry powder, free-flowing and applied electrostatically. Finally, cure it under direct heat or ultraviolet light to give it a glossy or semi-glossy finish.

Do you want your CNC-machined prototypes and parts to be wear and corrosion-resistant? An anodized surface finish allows hardness to the metal surface, making it ideal for automobile, aircraft, and mechanical parts.

Mostly, in the automotive sector, the demand for the electroplating process is high to make aluminum, stainless steel, or steel parts to make them functional, aesthetic, and corrosion-resistant. It gives a smooth and glossy finish.

For CNC machined parts, we use brushing as a surface treatment to give ABS, brass, aluminum, and steel prototypes and parts a satin finish. Here, we use abrasive belts to draw traces on these material surfaces to enhance aesthetics.

Polishing is a great way to give your CNC machined steel, brass, or aluminum parts a shiny and smooth finish through physical rubbing or chemical interference, like vapor polishing and fire polishing, so the surface has a breathtaking reflection.

Once you upload your 2D or 3D CAD files on our website, we evaluate it in no time and get back to you with an estimated price and DFM feedback in just 3 hours or less.

At CreateProto, we are ISO 9001:2015 accredited with years of experience in manufacturing CNC machining services and producing CNC parts with precision. We use the highest quality raw materials. (if parts do not meet standards, 100% rework or refund).

Our custom CNC machined components with the perfect precision and accuracy. Our professional engineers make the right measurements while offering product dimension details so you can ensure specific applications.

We guarantee excellence and precision for all the custom CNC machined prototypes and parts we manufacture. Quality is our priority. At our CNC machining company we provide our customers with the details of all the materials used in the production.

CNC (Computer Numerical Control) Machining is a manufacturing process to create detailed components eliminating material layers using precise machining and tooling to meet the exact specification.

The process is designed by CAD software and converted into machine commands. CNC machines read those commands and cut, shape, and produce the finished part with precision matching your digital design.

The best advantage you can take from CNC machining is unmatched accuracy and repeatability. Also, it can handle a variety of materials, from plastics to metals, while offering fast turnarounds and consistent quality, making it the best choice for industrial applications.

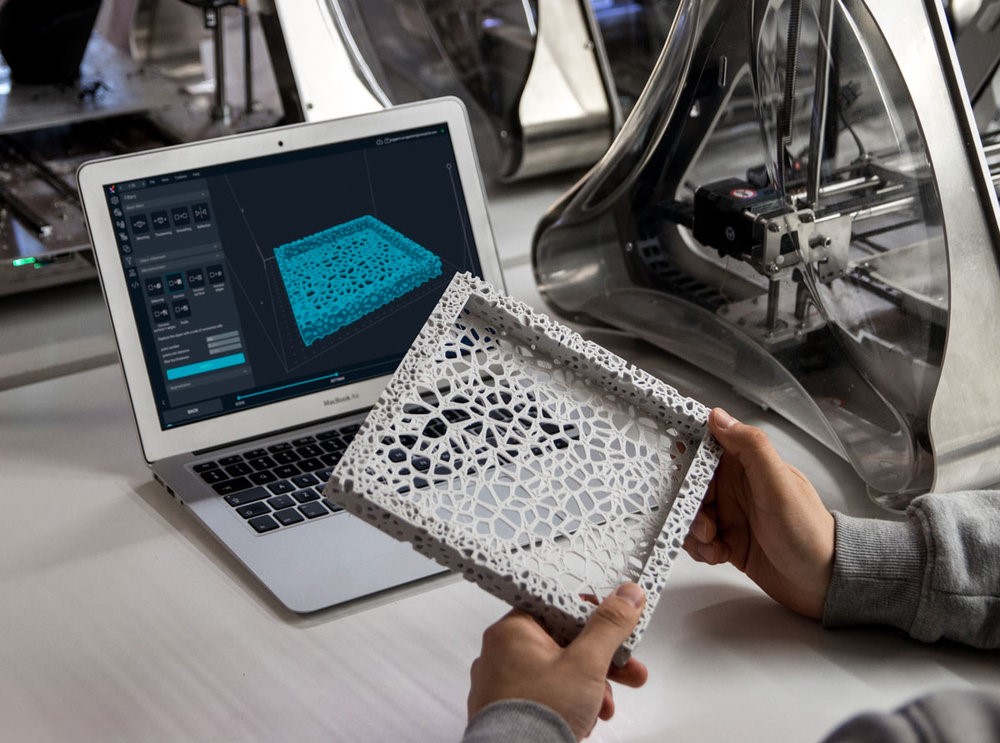

CNC machining is a subtractive process (removing parts from the initial material block) and 3D Printing is an additive manufacturing procedure (depositing material layer by layer). 3D printing is best for rapid prototyping and complicated geometries, whereas CNC machining is ideal for versatility, precision, and durability.

The maximum dimensions for CNC machining are 2000 mm x 1500 mm x 300 mm to facilitate large machined parts and prototyping for plastics and metals. Using this measurement, we can also accommodate tailored parts for different applications.

Yes, we follow the highest accuracy of metal components, which is +/-0.01and +/-0.02 for plastic parts, to ensure higher precision. However, as per requirements, we also meet the tolerances needed.

We have a huge team of technical experts to meet on-demand production with more than 100 mills, 3D printers, lathes, and other mechanical tools. Our capacity to produce CNC parts is up to 10,000+ parts within two weeks.

We use aluminum, brass, stainless steel, steel, bronze, ABS, and copper to produce CNC machined parts. However, the availability of specific materials can be different.

At CreateProto, our price for CNC machined parts starts from around $65 but can be varied based on your desired product design, complexity, choice of materials, and quantities. So, get a quote before for an estimated price!

We supply for both small and large-scale low-volume productions and rapid prototyping. So, whatever your needs are, we strive to meet on-demand production.

It depends on your design complexity, choice of material, and our current workload. However, with CNC machining, you can expect a fast turnaround, quality consistency, and in-time delivery.