CNC aluminium machining services – Get an instant quote on precision machining and manufacturing of aluminum alloy enclosures, frames, and complex geometric parts. We also offer surface treatments such as anodizing in various colors, polishing, matte oxidation, and more.

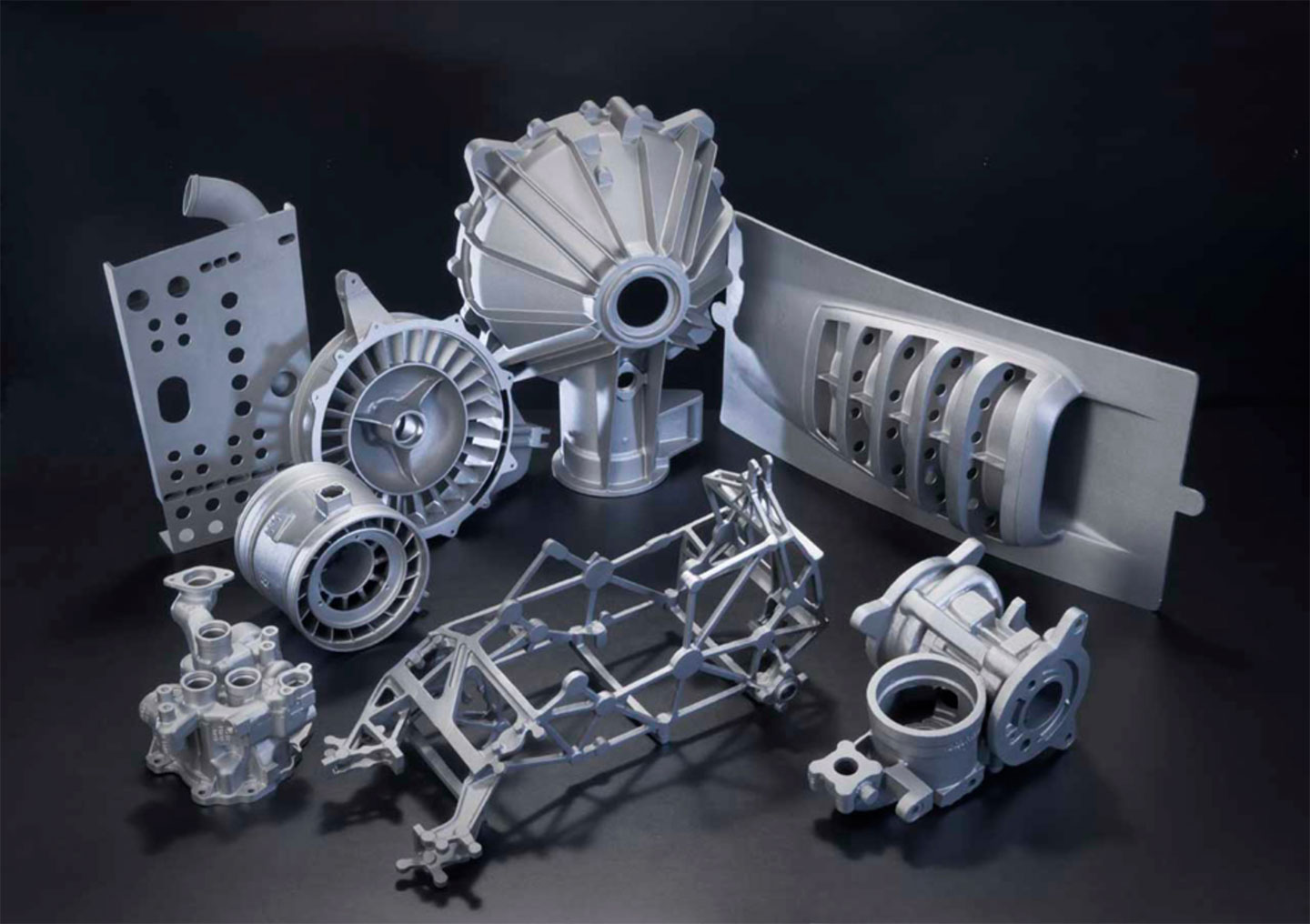

Looking to get your metal or plastic parts machined with complex geometries? At CreateProto, we offer different custom CNC aluminium services, including:

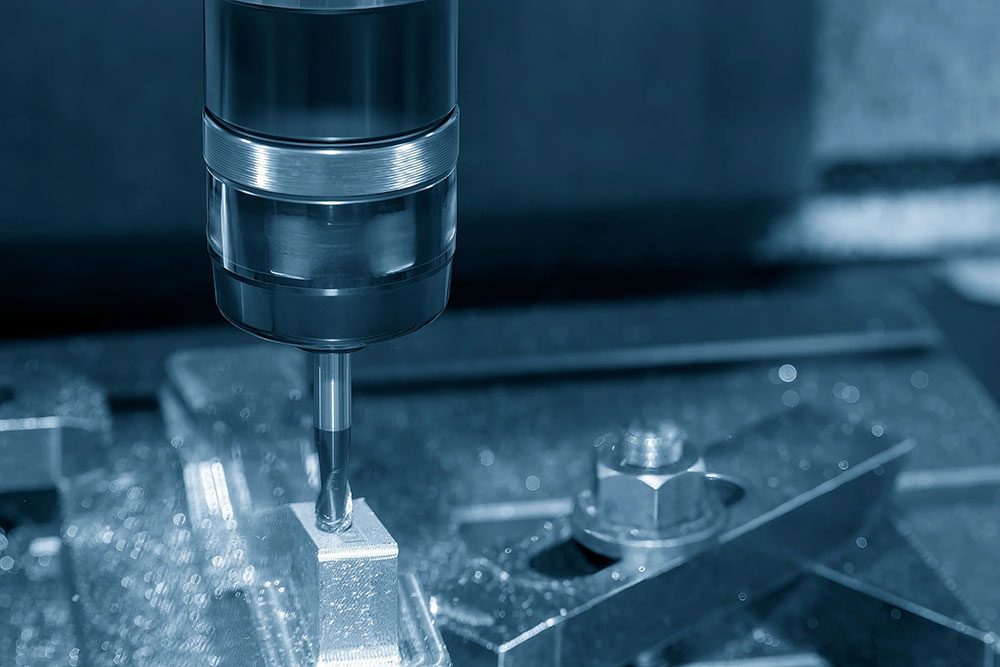

Dive into the world of precision with our top-notch aluminium CNC milling service! This is a cutting-edge process where a rotational cutting tool moves across a raw workpiece, sculpting the final CNC aluminium parts to perfection.

Our CNC aluminum service boasts both 3, 4 and 5-axis systems, ensuring your parts emerge with unparalleled precision and finesse.

So, why wait? Trust our CNC aluminum milling service to turn your visions into impeccably machined.

Rev up your manufacturing process with our aluminium CNC turning services! Here is the process: a blank mounted on a rotating chunk, eagerly awaiting the precision of our cutting tools to bring it to life. Our aluminum CNC machining isn’t just about churning out parts; it’s a symphony of speed and accuracy.

You don’t have to wait long and pay hefty prices – our aluminium CNC turning service delivers rapid production without breaking the bank. Embrace the efficiency of turning, where every rotation crafts your vision into reality!

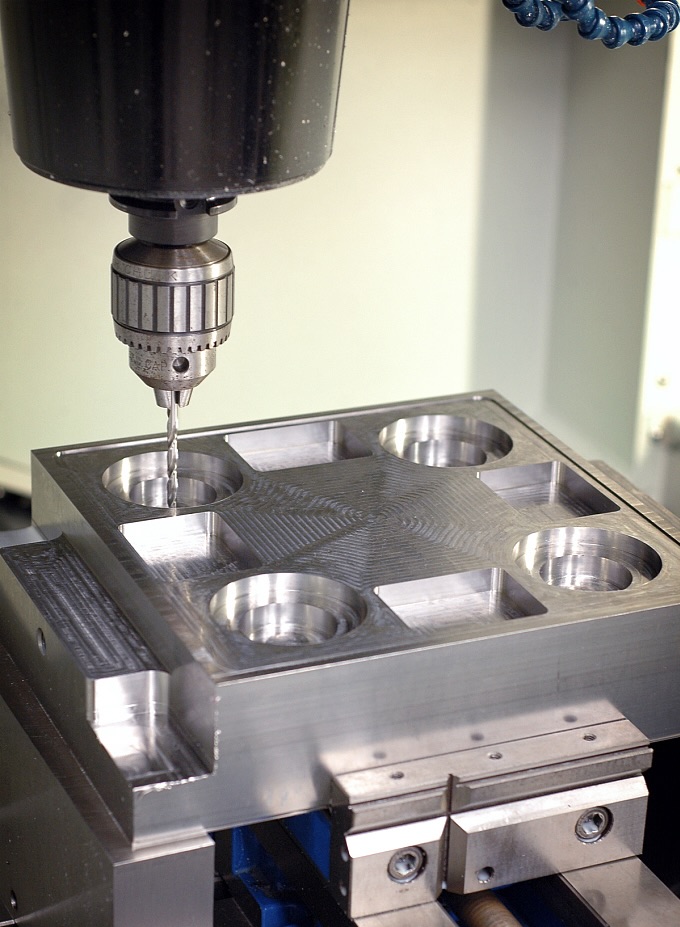

Discover the precision of CNC routing with our advanced technology! Much like aluminium CNC milling, our CNC routing excels at cutting, engraving, and carving materials from the workpiece.

This process ensures the meticulous crafting of aluminium CNC machining parts, reducing errors significantly compared to hand-held routers. Experience a leap in accuracy and efficiency as our state-of-the-art CNC routing delivers flawless results.

Bid farewell to manual inconsistencies and embrace the future of precision engineering with our superior CNC routing services, where every detail is perfect.

At CreateProto, Our intuitive Quick Quote provides instant pricing on approved designs for both metal and plastic parts within 3 hours. Our CNC aluminium service offers tighter tolerances, volume pricing, and anodizing with on-time production across industries, including aerospace, automotive, electronic, and healthcare sectors.

We can offer our clients fast comprehensive design analysis for any custom CNC part manufacturing within a few hours. Thanks to our advanced machine learning algorithm to identify the geometry complexity quickly!

You can get an instant quotation just a few hours after you upload your design files. We strive to provide competitive prices for CNC aluminium machining with FREE analysis for quality aluminium cnc machining parts.

For rapid prototyping and custom low-volume CNC aluminium machining, we ensure quick turnarounds and cost-cutting with our advanced additive manufacturing technology. With our efficient machined aluminium process, we optimize your time and costs. Lead time less than 7 days.

Our CNC aluminium rapid prototyping offers versatile and custom full-scale manufacturing from aerospace to automotive to medical industries. You can rest assured about precise, quick-turn, and on-demand parts production within the shortest time.

After getting an instant quote and DFM analysis within a few hours, you can look forward to receiving the CNC aluminium prototypes within the shortest time, testing, and bringing them to the market.

At CreateProto, we strive to offer seamless CNC aluminium prototyping to give the parts you want to get machined a complete transition. Our experts offer accurate DFM analysis and design for your low-volume production.

Whether you need rapid prototyping or low-volume production, we ensure fast delivery on demand. From 3D files, our experts quickly identify complex geometries and features and get them machined on time.

At Createproto, we use different materials to complete the rapid prototyping. Here are some of you can choose as per your manufacturing needs after getting an instant quote.

(6061/6061-T6/ 6063 / 7071/7075 / 5052…)

Aluminium is a thin metal, making it easy to machine. Due to its good strength-to-weight ratio, it’s used for different applications.

It is a low-carbon steel containing different properties, making it the most sought-after for various industrial applications.

It is an alloy of carbon and iron, popular for industrial applications due to its corrosion resistance, toughness, and hardenability.

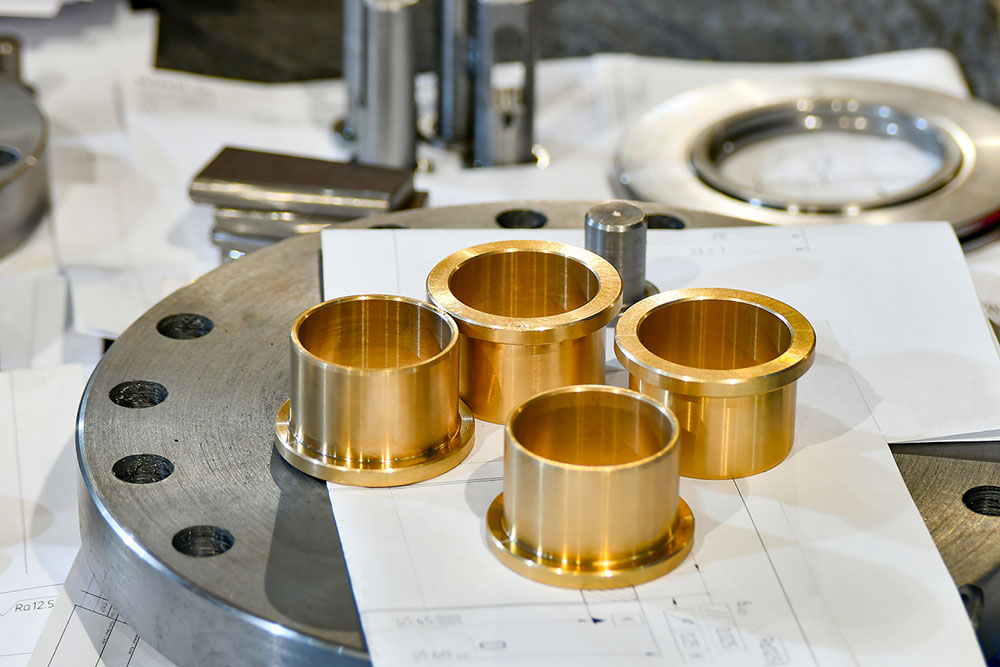

For different industrial applications, Brass is a popular material for CNC machining due to its low friction and electrical conductivity.

Copper has a high level of thermal and electrical conductivity and plasticity. Also, it’s easily welded and corrosion-resistant.

Bronze is an alloy consisting of copper, tin, and other metals. It’s used in a variety of applications due to its machinability, strength, and ductility.

Most raw aluminium comes with a dull silver finish or gray, which varies based on its surface roughness. For custom parts, you can choose from different surface finishes to enhance its aesthetics.

Bead blasting offers both matte texture and smooth surface used for visual applications and different surface treatments for steel, brass, stainless steel, and aluminium machined parts. For plastic parts, injection molding is used to bring that matte finish.

It’s applied as a dry and free-flowing powder electrostatically and cured with ultraviolet light or under heat. On aluminium, stainless steel, and steel machined parts, powder coating finishes are quite common.

For aluminium CNC machining, it’s the best surface finish to choose to improve its corrosion resistance and hardness. Due to its protected metal surface, it’s widely used in aerospace, automotive, and mechanical industries.

Electroplating is used across industries, including aerospace, medical, and even automotive sectors for chrome-plating of steel car parts. It’s not just decorative but functional and corrosion-resistant for steel, aluminium, and stainless steel CNC machining parts.

For aluminium, brass, and steel machined parts, you can choose to brush for surface finish to give an aesthetic look to your products. It’s used to draw traces on the material surface.

For a smooth and shiny surface, you can choose the polishing process for the surface finish of your cnc machining aluminium parts

Once you upload your 2D or 3D files on our platform, our cnc machining company team will provide DFM analysis and price estimates within a few hours. With a quick quote, you can get faster manufacturing and delivery.

CreateProto has years of experience and certified professional engineers to provide quality CNC machining service. Also, we use the highest quality materials for the manufacturing process. (if parts do not meet standards, 100% rework or refund).)

Besides a quick quote and faster ordering process, our experts strive to meet on-demand production with fast lead time using state-of-the-art machinery to speed up rapid prototyping and low-volume production.

We offer 24/7 engineering support, no matter where you are. Our experts offer the best solution for your custom CNC design, prototype, material selection, and surface finishing, considering the lead time.

The expenses for CNC machining services are variable depending on different attributes, from its design to tolerance specifications. Also, if the material you choose has a longer machining duration, it can affect the cost.

Lead time depends on the complexity of the prototype for part design, material, and our current workload. However, our experts strive to meet on-demand production within the shortest time and deliver parts within 5 days.

Why not? Our general tolerance in aluminum CNC machining components is DIN-ISO-2768 (fine) for machined metals and DIN-ISO-2768 (medium) for machined plastic parts. If you want more precision, the cost can increase.

Yes, for sure. We use state-of-the-art CNC machines to meet on-demand production of clients with the capability to produce over 10,000 prototypes using rapid prototyping tools and a huge number of technical experts.