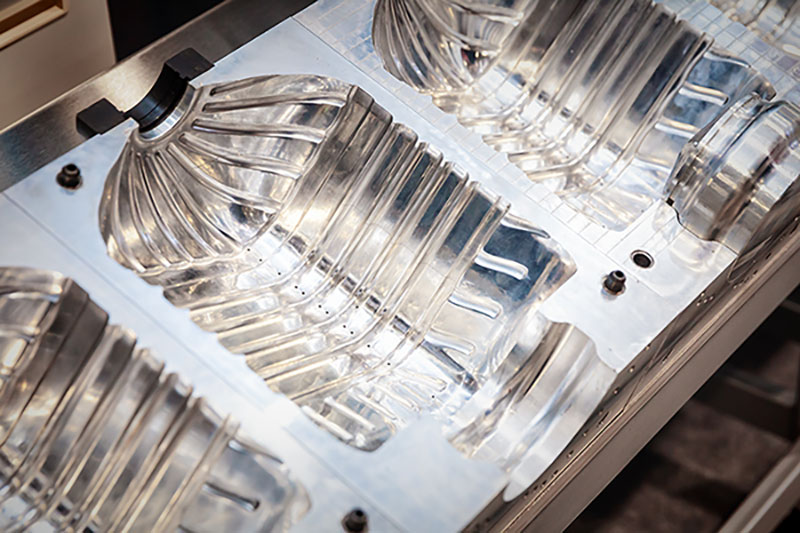

CreateProto leverages the rapid injection molding and tooling services to produce high-quality prototypes and small batches of components. This manufacturing approach allows us to maintain high standards while reducing costs and lead times.

Plastic injection molding is outstanding for crafting thousands of plastic parts copies. Commonly used to produce products like toys, electronics, and medical devices, the process is a versatile one.

Polyurethane vacuum casting is a popular technique that offers high-quality & low-volume parts. Get the exact results and detailed replicas as you desire.

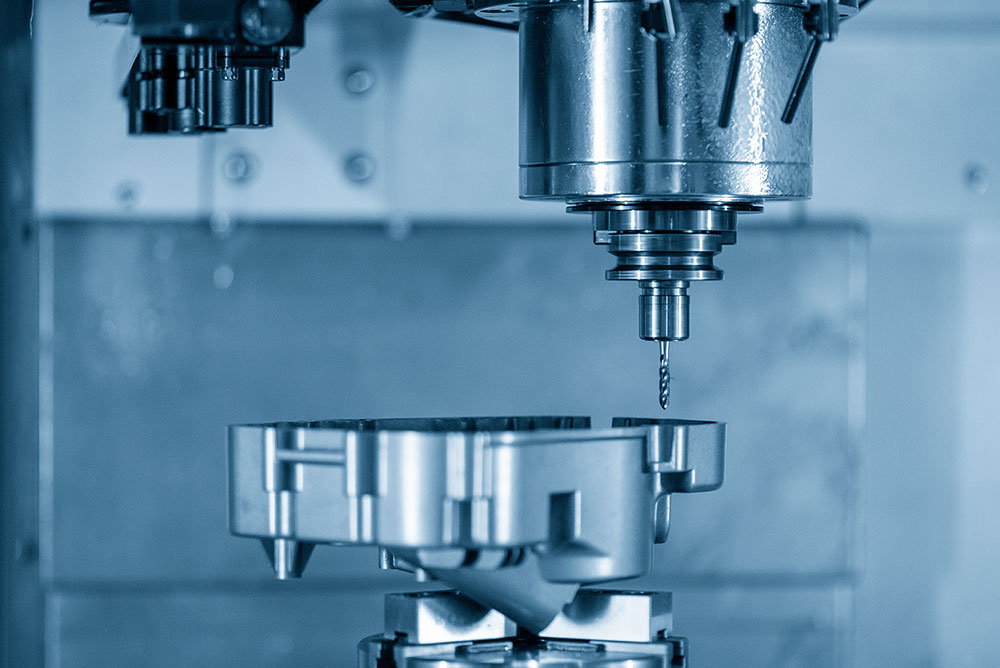

Also known as computer numerical control machining, this subtractive manufacturing process produces a wide variety of precision components across various industries, including aerospace, automotive, and medical devices.

Trust Createproto, the best in the business for low-volume manufacturing services. We offer top-quality products, competitive prices, and fast turnaround times. Our team is experienced in serving similar projects with a variety of materials and manufacturing processes.

Createproto is devoted to offering high-quality products meeting the fine requirements of our clients. We promise to use the best quality material and state-of-the-art manufacturing processes to manufacture durable and aesthetically pleasing products.

We believe in reaching clients of all kinds. Thus, we make sure that our services are affordable and competitive. We'll work with you to find a solution that fits your budget and needs.

We understand the importance of time in every manufacturing process. Thus, we strive to offer faster turnaround times for all our projects. We work closely with our clients to know about your timeline and needs.

Our journey of low-volume production initiates with you. Then we work with you to create a custom manufacturing plan. We implement the latest processes to produce high-quality products to get your product ready for market.

The first step in low-volume manufacturing involves a proper understanding of customer’s needs and requirements. This step consists of brainstorming, sketching, and crafting initial prototypes to refine the product concept.

Once the design is finalized, it’s time to implement the detailed specifications. This stage includes the creation of 3D models, conducting simulations, and optimizing the design for manufacturability.

The last and final stage includes the selection of appropriate manufacturing techniques, sourcing high-quality materials, and executing the manufacturing process with precision to meet the highest customer satisfaction.

The outstanding strength, durability, and affordability make it one of the most versatile choices for low-volume manufacturing.

Lead Time: 1-2 weeks

Tolerances: ±0.005mm

It is a durable option offering corrosion-resistant features. Popularly used in this manufacturing process, the material offers longevity and aesthetic appeal to the manufactured products.

The outstanding strength, durability, and affordability make it one of the most versatile choices for low-volume manufacturing.

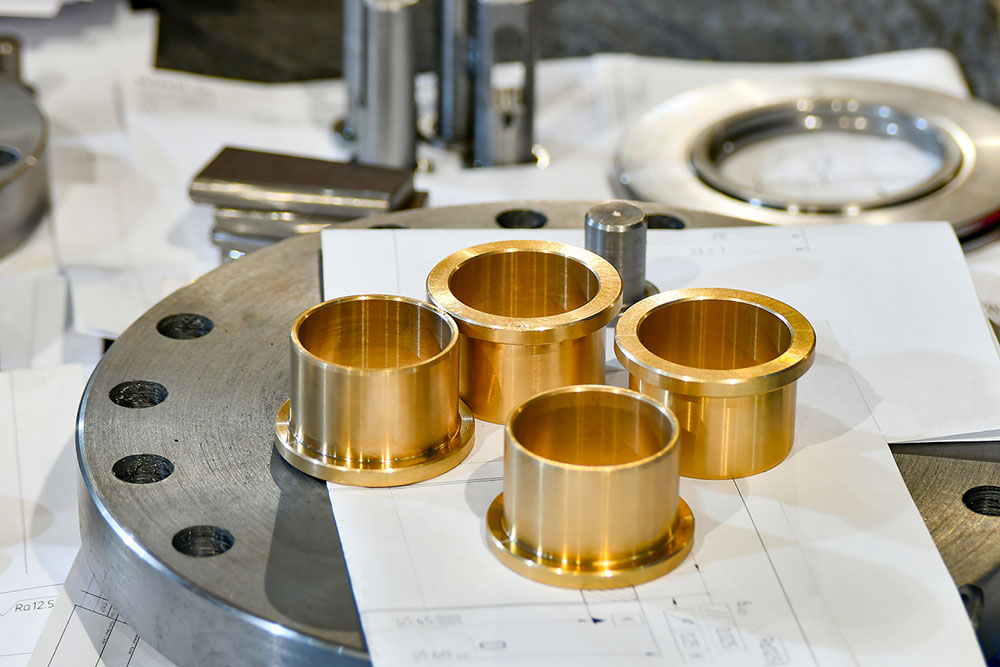

Brass is a common alloy, well-suited for low-volume manufacturing of intricate parts, decorative items, and functional components.

Copper’s excellent electrical conductivity, thermal conductivity, and malleability make it a valuable and ideal material for low-volume manufacturing.

With the combination of strength, durability, and corrosion resistance, bronze is a sought-after material for perfect low-volume manufacturing.

Low-volume manufacturing and CNC machining offer a plethora of benefits, making it a captivating option for businesses of all sizes. Get reduced overhead costs, greater design flexibility, faster time to market, customized solutions, bridge production, and much more.

Our custom machining service involves usage of computer-controlled machines to cut and shape materials into precise shapes.

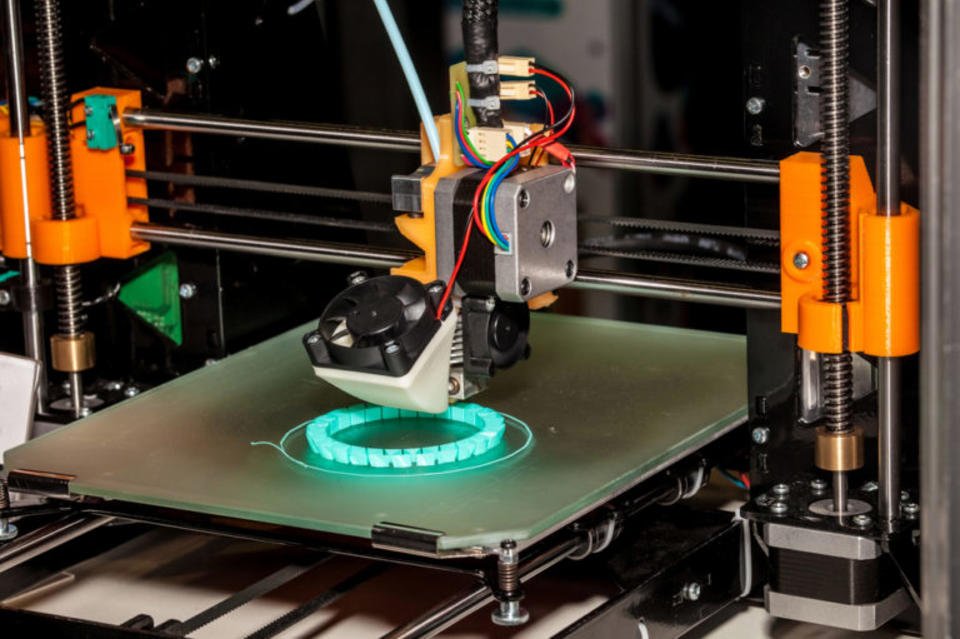

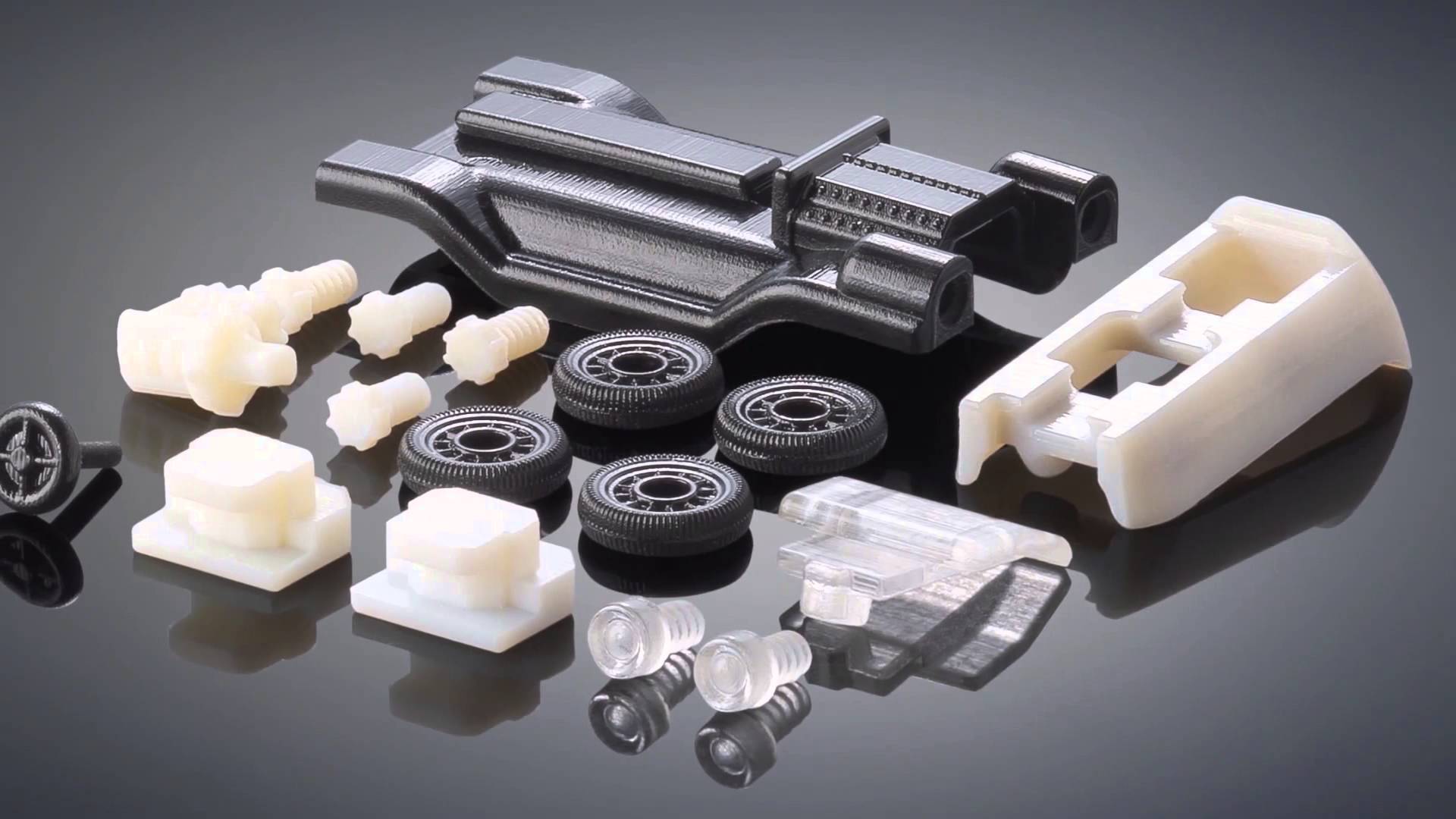

This process uses additive manufacturing to create products from layers of material.

This process uses a mold to create products from molten plastic.

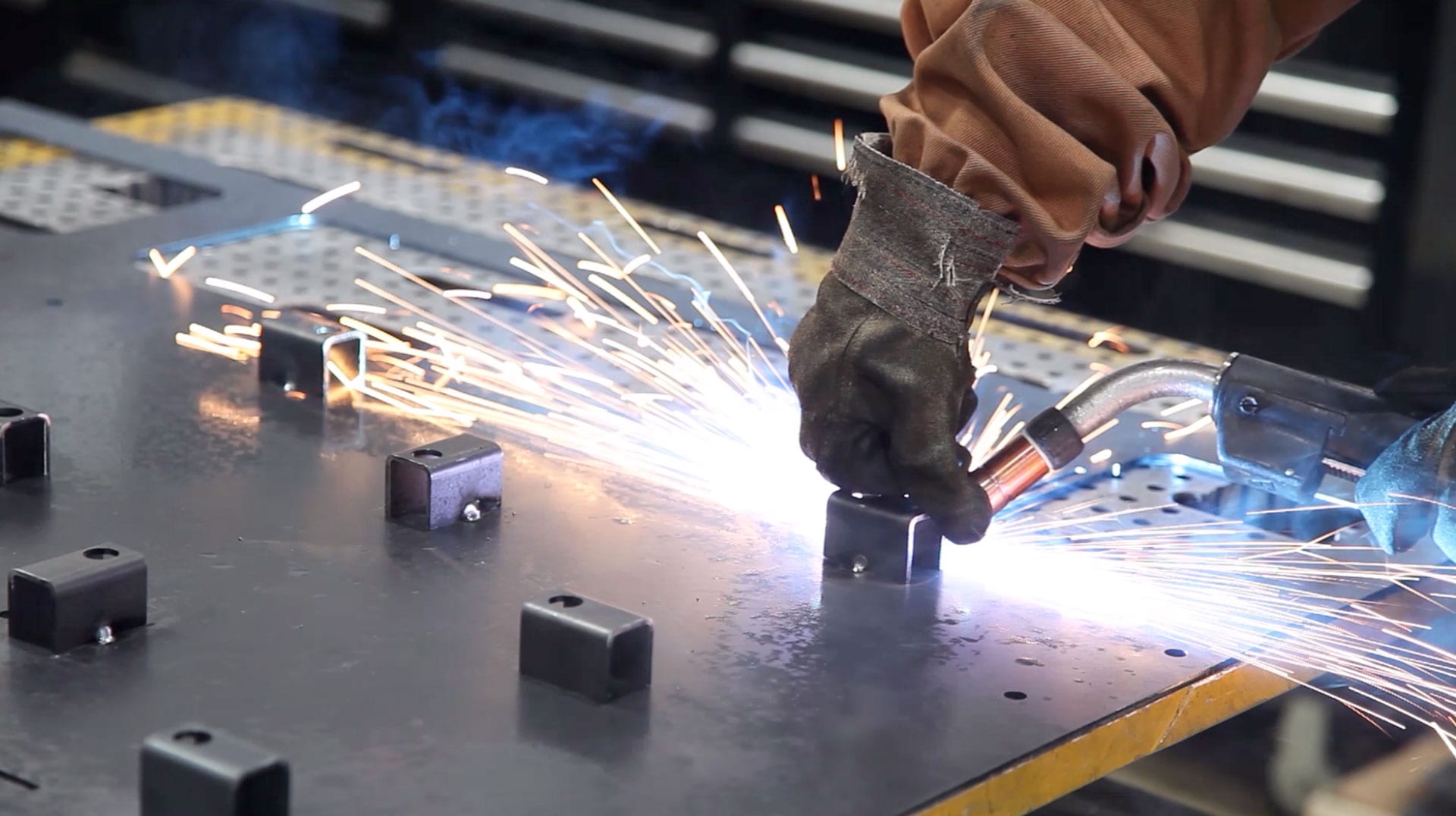

This process involves cutting, bending, and forming sheet metal into various shapes.

Low-volume manufacturing services can be used to create prototypes of new products, test their products, and make changes before investing in full-scale production.

It can be used to produce small quantities of products for niche markets or for products that are in the early stages of development.

Utilize this useful process to create customized products that meet the specific needs of customers. This can be a good option to create products with unique features.

Our unwavering commitment to serving our global partners extends beyond mere production. We take pride in offering a comprehensive suite of in-house manufacturing services, skillfully executed with industry-leading agility.

Our team of engineers and technicians possesses a collective wealth of experience spanning centuries. Over the years, we have proudly partnered with countless organizations, assisting them in transforming their groundbreaking ideas into tangible products.

The creation of exceptional products requires unwavering commitment. We understand this fundamental principle and have established industry-leading material verification to ensure that your products are crafted from the finest materials available.

We recognize that the journey from concept to creation can be a complex one. To ensure a seamless and collaborative process, we provide our clients with a comprehensive design for manufacturing support.

It’s been two times we have worked with CreateProto, and honestly, they have never disappointed us. We just requested the quote, and they have handled the rest, from product design to production to testing and launch- All the fulfillment required for our projects so far. Professionalism and convenience- Perfect reasons to work with them!

Avram Mckinney Mechanical Engineer Associate, Thermaco

It’s really impressive working with CreateProto for our automotive projects. Quick responses all the time that has eased communication. We don’t have to manage or juggle suppliers. They got us all covered! In fact, their prices are too competitive, even for mass customization and low-volume production.

Timothy Frederick CAE Mechanical Engineer, BirdWe offer an extensive variety of outstanding in-house services including CNC machining, vacuum casting, plastic injection molding, and finishing, marking us as the finest in the industry.

Yes, our expert teams are masters at manufacturing with additional offerings such as high-quality control and aesthetic outcomes.

Createproto's low-volume production parts are guaranteed by rigorous quality control standards. This includes incoming material inspection, in-process inspection, and testing.

Whenever and whatever we have needed, Createproto has delivered every time with the exact precision and quality required. Faster turnarounds, perfect finish, and on-time delivery for product launch- Great experience working with them. We appreciate their professionalism and are looking forward to teaming up with them again.

Tyler Richards Lead Mechanical Engineer, Shimano