Metal fabrication – an important process that transforms raw materials into custom parts and components that are used in different industries. For instance, the building and construction industries use a lot of fabricated metals. And, other industries like farming, aerospace, aircraft, etc also depend on this.

Metal fabrication is also necessary to make things like steel cans, blinds, steel roofs, door handles, grills, heaters, chairs, silverware, fans, locks, keys and more.

So, businesses and engineers, looking for dependable metal fabrication services, just need to spend their valuable 5 minutes and read this blog. You will discover metal fabrication techniques and the most reliable service provider too.

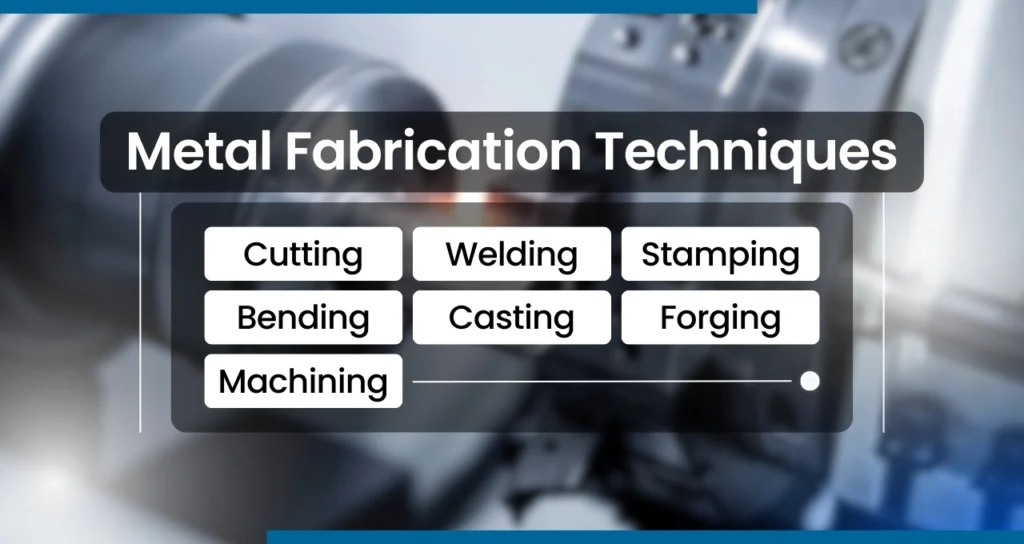

Let’s Know about Metal Fabrication Techniques

Cutting

Cutting is a fundamental and important technique in metal fabrication. So, it involves slicing metal sheets or plates to get the desired size or shape. If we talk about the past, like a few decades back, cutting was done with saws, but not anymore! Now, there are more advanced methods like laser cutting, plasma cutting and water jet cutting.

Welding

Welding is a method that joins two or more pieces of metal by melting their edges and adding filler material to create a strong bond. You will be surprised to know there are various welding techniques too – each suited to different types of metal, thicknesses and uses.

Each welding method has its own advantages, making it one of the most commonly used techniques in metal fabrication.

Stamping

Stamping is a process that involves pressing metal into specific shapes using a die. This technique is useful for creating a large volume of identical metal parts, like car doors or electronic components.

Stamping process is primarily used in the automotive, electronics, and home appliance industries. Its speed and affordability make it invaluable for mass production(although initial die costs can be high).

Bending

Bending is a straightforward technique where metal is actually reshaped by applying pressure without cutting. This technique is typically done with press brakes, a machine that bends metal into different angles.

Bending is highly versatile and it is used to make anything from furniture frames to machine parts. It’s a go-to technique in the construction, automotive, and manufacturing industries.

Casting

Casting involves pouring liquid metal into a mold where it cools and solidifies into the desired shape. This technique is highly efficient for creating complex shapes and large metal parts.

Commonly used in automotive engine manufacturing, heavy machinery, and tooling industries, casting allows for intricate designs that might be too challenging with other methods. Metal parts like engine blocks, propellers, and even statues are often made through casting.

Forging

Forging is a traditional way of working with metal. It involves heating the metal until it becomes soft and easy to shape, then using tools like hammers or presses to give it the right form. This method makes strong and long-lasting parts.

You often see forged parts in important places like the aerospace, automotive, and oil and gas industries, where strength is at the top of the list of priorities.

Machining

Machining removes material from a piece of metal and this process helps to achieve the desired shape. Here, cutting tools like drills, lathes, and mills are used. It’s a high-precision technique used when specific details are a must.

Industries like aerospace, medical devices, and electronics prefer the machining process for producing intricate parts like screws, gears, and turbine blades.

Choosing the Right Metal Fabrication Technique

With CreateProto Rapid System Limited, now getting a personalized quote for custom metal fabrication services is now just a few clicks away.

Use our Quick Quote tool to submit your part design, and we’ll provide you with an estimated cost within 3 hours!

We operate our own factory, offering a full range of precision metal and plastic part processing services. All our parts and equipment are certified under ISO 9001:2015 and IATF16949 standards.

So, whether you need metal fabrication services, injection molding, custom CNC milling, or custom 3D printing, we will make sure your product design is developed with the utmost attention to detail.

And, the good news is all our manufactured parts come with comprehensive after-sales support (if parts don’t meet standards, we offer 100% rework or a full refund).

Visit our website! Get an instant quote now!