CNC turning – You might have surely heard about it before. But, it’s always a good thing to have a clear idea on how it works. In today’s blog, we’ll break down the fundamental operations of CNC turning so you can really grasp the basics and get the most out of this information.

How a CNC Lathe Machine Does Its Magic

In simple words, CNC lathe is like a high-tech sculptor. Here, instead of adding material, it basically takes the material away to create amazing shapes.

Here’s how it works

CNC turning is a machining process and it uses computer-controlled lathes to create cylindrical parts. Now it’s really important to know how this CNC lathe operates:

The process starts with a workpiece – that is the material that will be shaped. This workpiece is held in a chuck and then rotates around what’s called the Z-axis. And, this rotation is the main motion in turning.

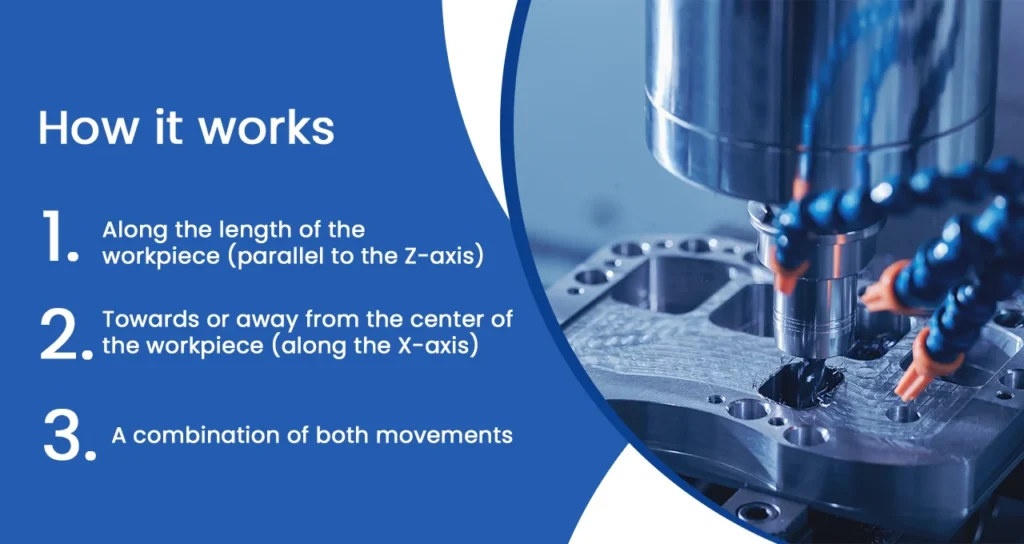

Now while the workplace spins, the Cutting Tool moves into position like in different directions:

- Along the length of the workpiece (parallel to the Z-axis)

- Towards or away from the center of the workpiece (along the X-axis)

- Or a combination of both movements

When the cutting tool contacts the spinning workpiece, it simply removes material. And, this is how the desired shape you can get. The interesting thing is the tool can create different features like straight cuts, steps or grooves, tapered shapes, etc.

Versatility in Machining Modern CNC lathes can do more than just simple turning. They’re capable of various operations, such as –

- Contour turning: creating complex curved shapes

- Facing: flattening the end of a workpiece

- Boring: making holes or enlarging existing ones

- Threading: cutting screw threads

- Grooving: making narrow channels or cuts

Key Components

If you’ve ever seen a CNC lathe up close, you can see it has many parts.

- Machine bed – The sturdy base that supports everything else

- Headstock – Houses the main spindle that spins the workpiece

- Feed gearbox – Controls the movement of the cutting tool

- Carriage – Holds and moves the cutting tool

- Tailstock – Supports long workpieces from the opposite end

- Chuck – Holds the workpiece securely as it spins

Different Types for Different Needs

CNC turning centers come in various types to suit different types of manufacturing needs. They’re usually classified based on two main features:

Number of Axes:

- 2-axis

- 3-axis

- 4-axis

- 5-axis

Spindle Orientation:

Vertical: The spindle points up and down, which is good for large, disc-shaped parts

Horizontal: The most common type, with the spindle parallel to the ground

What Can They Make?

CNC turning centers are great for making round parts, like shafts of various sizes, pulleys, threaded rods, gun barrels, camshafts, crankshafts and many more! And, if it is about round or cylindrical, then CNC lathe can surely make it.

CNC Lathes – Why They’re a Manufacturing Favorite

Lathes have been popular for a long time, but they have come a long way from their early days. Today’s CNC (Computer Numerical Control) lathes are very different.

Nowadays, CNC lathes can work much faster than manual machines. They don’t need to pause for the operator to make adjustments or measurements. So, this speeds up the whole process.

Since the advancement of computer control, CNC lathes can make parts with very high precision. This accuracy is really important for many industries.

Once programmed, CNC lathes can run with minimal human intervention. As a result, it reduces labor costs and allows for long operations.

There are many different types of CNC lathes available at current times. This variety means that manufacturers can find a lathe that is suited to the specific needs of the client for small precision parts or large industrial components.

Perks of CNC Turning

Using CNC turning for manufacturing comes with several benefits:

- The combination of spinning workpieces and moving tools simply allows for fast, accurate production.

- Since the process is automated, there’s less chance of human error. So, there is less wasted material.

- In this process, tool changes and setup times are minimized. So, it keeps the machine working more of the time.

- Operators don’t need to be right next to the machine while it’s working – so it reduces the risk of accidents.

Bottom Line

So, we hope this blog gives you all the necessary information on CNC turning.

If you need CNC turning services, Createproto Rapid System Limited can help. We only operate using tools that are ISO 9001:2015 certified.

With us, you will get quick lead times and the most affordable pricing. We specialize in custom CNC turning services, CNC milling, metal fabrication services, laser engraving, metal and plastic injection molding, ultrasonic welding, and many more!

Visit our website and get a quick quote today!

If you have any questions, our experts can help you with them!