When it comes to modern manufacturing, Steel CNC machining plays an important role in creating complex parts with minimal waste. Aerospace, automotive, and construction industries, in particular, use CNC machining to produce high-quality steel components. So how does the process go? Knowing all the steps is important to realizing the degree of accuracy involved.

CNC (Computer Numerical Control) machining is a subtractive manufacturing process. It takes away material from a solid steel workpiece to give it the desired shape. Pre-programmed software controls the process, which ensures accuracy and consistency. Whether cutting, drilling, or milling, CNC machining for steel produces outstanding results.

Steel is a hard material, and machining it requires special tools and methods. Well, unlike softer metals, steel needs high-speed cutting, cooling, and robust tooling to avoid wear and tear.

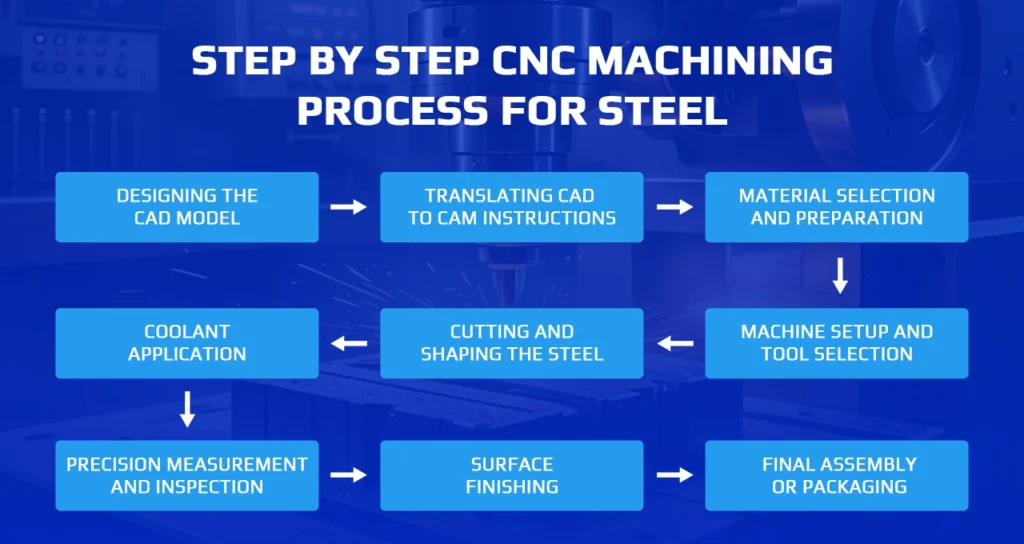

Let’s understand the CNC machining process for steel, step by step.

Designing the CAD Model

It all starts with a very precise CAD (Computer-Aided Design) model. Engineers design a virtual replica of the part. The model contains dimensions, tolerances, and material composition. CAD software here makes sure that the design is accurate before the machining takes place.

Translating CAD to CAM Instructions

When the CAD design is complete, it is translated into CAM instructions. CAM software converts the design into G-code, which is the language understood by CNC machines. G-code tells the cutting tools where to move in order to produce precision.

Material Selection and Preparation

Well, the manufacturers must decide on the proper steel grade. Various types, including carbon steel, stainless steel, and tool steel, possess distinct characteristics. The steel workpiece is then fixed on the CNC machine to avoid movement while machining.

Machine Setup and Tool Selection

The CNC machine is set up according to the requirements of the job. Operators choose suitable cutting tools, including end mills, drills, or lathe inserts. Tool choice here is based on certain considerations such as steel hardness, finish required, and machining operation.

Cutting and Shaping the Steel

The machining process starts. Cutting tools shave off excess material, giving shape to the steel piece. Typical CNC operations are:

Milling: Spinning tools cut away material to produce accurate shapes.

Turning: The workpiece is rotated as a fixed tool that takes away material.

Drilling: Holes are made using high-speed drill bits.

Grinding: Polishes surfaces and improves finish quality.

Coolant Application

Machining steel produces heat. Too much heat can ruin tools and change material properties. Coolants or lubricants are used to keep temperatures in check and enhance tool life.

Precision Measurement and Inspection

Part quality is checked after machining. The use of tools such as calipers, micrometers, and coordinate measuring machines (CMM) assures dimension and tolerance. Any errors are rectified before advancing to the next step.

Surface Finishing

Steel parts can have extra finishing steps. It may involve polishing, coating, or anodizing for improved durability and looks. Finishing provides the desired industry standards for the final product.

Final Assembly or Packaging

After machining and finishing are completed, parts are assembled into larger components or packaged for shipping. Careful handling ensures steel parts are in perfect condition until reaching the customer.

Final words

If you’re looking for a top-notch company to handle the CNC machining needs for steel, consider approaching Createproto Rapid System Limited.

We only source high-quality raw materials to make sure each component is durable and reliable. You will get different types of material options for rapid prototyping of custom complicated parts.

You can choose the machining materials like aluminum, steel, plastic, stainless steel, bronze, brass, copper, etc. depending on your manufacturing needs, budget, and required lead time.

Reasons to choose us-

- Utmost Precision for machining with tight tolerances

- 3-Axis, 4-Axis & 5-Axis, Swiss CNC Machining

- Competitive prices when compared to the US and European markets

- Quick turnaround times for on-time delivery

Visit our official website for more details! Or, get a quick quote now!